Key Insights

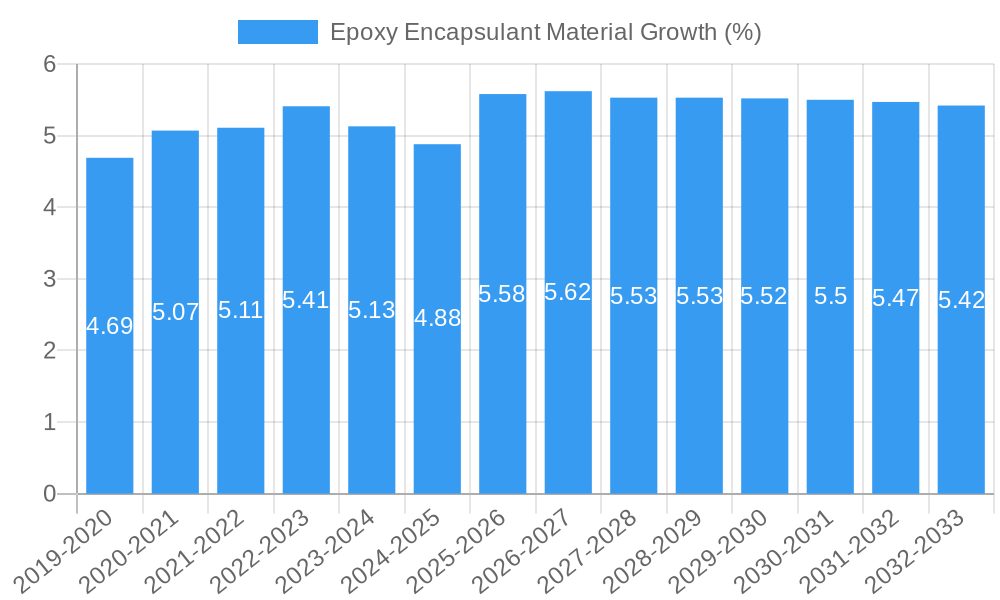

The global Epoxy Encapsulant Material market is experiencing robust expansion, driven by the ever-increasing demand for advanced semiconductor devices and intricate electronic components. With a projected market size of approximately $4,500 million by 2025, this sector is poised for significant growth, anticipated to expand at a Compound Annual Growth Rate (CAGR) of around 7.5% through 2033. This upward trajectory is primarily fueled by the escalating adoption of epoxy encapsulants in semiconductor packaging, where their superior dielectric properties, thermal stability, and mechanical protection are paramount for ensuring the reliability and longevity of sensitive integrated circuits. Furthermore, the burgeoning consumer electronics, automotive, and telecommunications industries, each heavily reliant on sophisticated electronic components, are acting as significant growth engines for this market. The trend towards miniaturization and higher performance in electronic devices further necessitates the use of advanced encapsulation materials, positioning epoxy encapsulants as a critical enabler of future technological advancements.

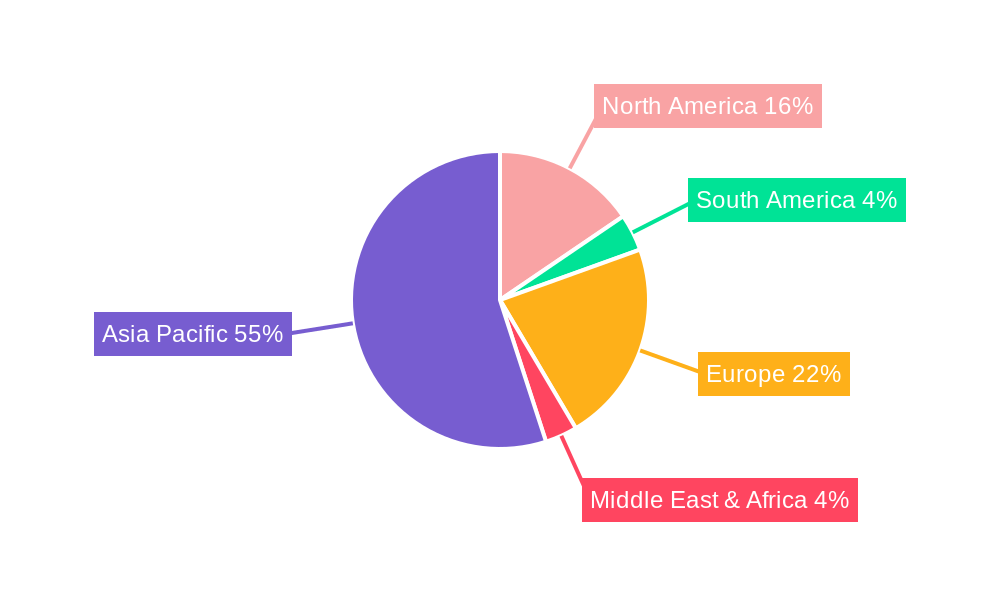

Despite the optimistic outlook, certain factors could pose challenges to the market's rapid ascent. The fluctuating costs of raw materials, particularly epichlorohydrin and bisphenol A, can impact profit margins for manufacturers and potentially influence pricing strategies. Additionally, the development and adoption of alternative encapsulation technologies, while not yet posing a significant threat, represent a potential area of competition. However, the inherent advantages of epoxy encapsulants in terms of performance, cost-effectiveness in many applications, and established manufacturing processes are expected to largely mitigate these restraints. The market is segmented into Normal Epoxy Molding Compound and Green Epoxy Molding Compound, with the latter gaining traction due to increasing environmental regulations and a growing consumer preference for sustainable products. Geographically, the Asia Pacific region, led by China and South Korea, is the dominant market and is expected to maintain its leadership due to its extensive manufacturing base for electronics and semiconductors.

Epoxy Encapsulant Material Market: Comprehensive Analysis and Future Outlook (2019–2033)

This in-depth market research report offers a comprehensive analysis of the global Epoxy Encapsulant Material market, providing critical insights for industry stakeholders. Covering the historical period from 2019 to 2024, the base year 2025, and a robust forecast period through 2033, this report meticulously examines market dynamics, growth trends, regional dominance, product landscapes, key drivers, barriers, challenges, emerging opportunities, and the competitive environment. The report leverages extensive primary and secondary research, presenting data in millions of units and incorporating high-traffic SEO keywords to maximize visibility and engagement with professionals in the electronics, semiconductor, and advanced materials sectors.

Epoxy Encapsulant Material Market Dynamics & Structure

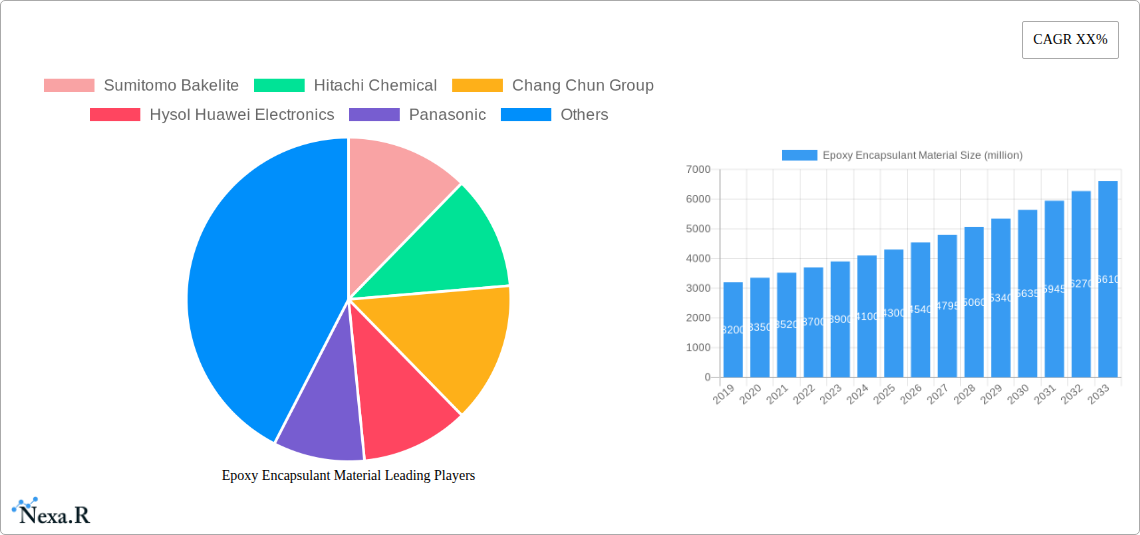

The Epoxy Encapsulant Material market exhibits a moderately concentrated structure, with key players like Sumitomo Bakelite, Hitachi Chemical, Chang Chun Group, and Hysol Huawei Electronics holding significant market shares. Technological innovation is a primary driver, particularly the demand for advanced encapsulation solutions that enhance the reliability, durability, and performance of electronic components and semiconductors. The push towards miniaturization and higher power densities in electronic devices directly fuels the need for sophisticated epoxy encapsulants. Regulatory frameworks, while evolving to address environmental concerns (e.g., RoHS compliance), generally support the growth of high-performance materials. Competitive product substitutes, such as silicones and polyurethanes, exist, but epoxy's superior adhesion, thermal stability, and electrical insulation properties in many applications maintain its dominance. End-user demographics are shifting towards sectors demanding higher reliability and smaller footprints, including automotive electronics, consumer electronics, and advanced industrial equipment. Merger and acquisition (M&A) trends are notable, with companies seeking to expand their product portfolios, gain access to new technologies, or strengthen their market presence. For instance, in the historical period, there were approximately 5 significant M&A deals valued in the hundreds of millions of dollars, aimed at consolidating market share and acquiring specialized encapsulation technologies. Innovation barriers include the high cost of R&D for novel formulations and the stringent qualification processes required by leading semiconductor manufacturers.

Epoxy Encapsulant Material Growth Trends & Insights

The global Epoxy Encapsulant Material market is projected to experience robust growth, driven by the relentless expansion of the electronics industry. The market size, estimated at $X,XXX million in the base year 2025, is expected to reach $Y,YYY million by 2033, exhibiting a Compound Annual Growth Rate (CAGR) of X.X% during the forecast period. This growth is underpinned by increasing adoption rates in the semiconductor encapsulation segment, which is the largest application, accounting for over 70% of the market. Technological disruptions, such as the rise of advanced packaging techniques like wafer-level packaging and 3D stacking, necessitate the use of specialized epoxy encapsulants with enhanced thermal management and electrical isolation properties. Consumer behavior shifts, including the demand for more durable and compact electronic devices across automotive, industrial, and consumer electronics sectors, are further accelerating market penetration. The increasing integration of electronic components in vehicles, from infotainment systems to advanced driver-assistance systems (ADAS), is a significant catalyst. Furthermore, the growing adoption of IoT devices and wearable technology, requiring highly reliable and miniaturized encapsulation solutions, contributes to this positive trend. The global market penetration of epoxy encapsulants in critical electronic applications is estimated to be around 85% in 2025. The development of green epoxy molding compounds, addressing environmental regulations and sustainability concerns, is also a key trend influencing adoption and market dynamics. The historical period saw a steady increase in the market size, growing from an estimated $A,AAA million in 2019 to $B,BBB million in 2024, reflecting consistent demand from the core industries. The market's resilience is further demonstrated by its ability to adapt to global supply chain fluctuations and evolving material requirements. The continuous innovation in material science, focusing on improved thermal conductivity, reduced warpage, and enhanced reliability under extreme conditions, will continue to drive demand.

Dominant Regions, Countries, or Segments in Epoxy Encapsulant Material

The Semiconductor Encapsulation application segment stands as the dominant force driving growth in the global Epoxy Encapsulant Material market. This segment is projected to account for approximately 75% of the total market value by 2033, underscoring its critical role. The dominance of semiconductor encapsulation is propelled by several key factors, including the ever-increasing demand for microchips across a multitude of industries such as consumer electronics, automotive, telecommunications, and artificial intelligence.

Key Drivers for Semiconductor Encapsulation Dominance:

- Exponential Growth in Semiconductor Demand: The proliferation of smartphones, 5G technology, cloud computing, and AI-powered devices directly translates to a surging requirement for advanced semiconductor packaging, where epoxy encapsulants are indispensable.

- Miniaturization and Performance Enhancement: The industry's relentless pursuit of smaller, faster, and more powerful chips mandates encapsulation materials that offer superior protection, thermal dissipation, and electrical insulation. Epoxy's ability to meet these stringent requirements makes it the material of choice.

- Technological Advancements in Packaging: Innovations like wafer-level packaging (WLP), 3D packaging, and heterogeneous integration demand specialized epoxy formulations with low cure shrinkage, high glass transition temperatures (Tg), and excellent adhesion to diverse substrates.

- Increased Investment in Foundries and R&D: Significant global investments in semiconductor manufacturing facilities and research and development activities further fuel the demand for high-quality encapsulation materials.

- Strict Reliability Standards: The critical nature of semiconductor devices in applications like automotive and medical devices necessitates encapsulation solutions that can withstand extreme environmental conditions, vibrations, and thermal cycling, areas where epoxy excels.

Regionally, Asia Pacific is the dominant market, holding an estimated 60% market share in 2025. This dominance is attributed to:

Asia Pacific's Dominance Factors:

- Manufacturing Hub: The region's status as a global manufacturing powerhouse for electronics and semiconductors, with major production facilities located in countries like China, South Korea, Taiwan, and Japan.

- Growing Domestic Demand: Rising disposable incomes and increasing adoption of advanced electronic devices in emerging economies within Asia Pacific are creating substantial domestic demand.

- Government Initiatives: Supportive government policies and incentives aimed at fostering local semiconductor manufacturing and technological innovation.

- Presence of Key Players: The concentration of leading semiconductor manufacturers and epoxy encapsulant producers within the region facilitates market growth and innovation.

Among the types, Normal Epoxy Molding Compound currently holds the largest market share, valued at approximately $XX,XXX million in 2025, due to its established use and cost-effectiveness in a wide range of applications. However, Green Epoxy Molding Compound is poised for significant growth, driven by increasing environmental regulations and a growing preference for sustainable materials, projected to grow at a CAGR of X.X% during the forecast period. The market size for Green Epoxy Molding Compound was estimated at $X,XXX million in 2025.

Epoxy Encapsulant Material Product Landscape

The Epoxy Encapsulant Material product landscape is characterized by continuous innovation focused on enhancing performance metrics critical for modern electronics. Manufacturers are developing advanced formulations offering superior thermal conductivity for efficient heat dissipation in high-power devices, alongside improved electrical insulation to prevent short circuits. Unique selling propositions often lie in achieving ultra-low warpage during molding and curing, crucial for the integrity of sensitive semiconductor packages. Technological advancements include the development of halogen-free epoxy molding compounds that meet stringent environmental regulations, as well as formulations with enhanced adhesion to dissimilar materials and higher glass transition temperatures (Tg) for increased operational reliability in extreme temperatures. Innovations also focus on faster cure times to improve manufacturing throughput and reduced moisture absorption for enhanced long-term stability.

Key Drivers, Barriers & Challenges in Epoxy Encapsulant Material

Key Drivers:

The Epoxy Encapsulant Material market is propelled by several key forces. The relentless demand for advanced semiconductors in 5G infrastructure, AI, and IoT devices is a primary technological driver. Economic factors, such as increasing global electronics production and automotive electrification, contribute significantly. Policy-driven factors, like government investments in semiconductor manufacturing and stricter reliability standards for electronic components, further fuel market expansion. The growth in demand for high-performance electronic components in consumer electronics and industrial automation are also major contributors.

Barriers & Challenges:

Despite the positive outlook, the market faces several challenges. Supply chain disruptions, particularly concerning raw material availability and price volatility, pose a significant restraint. Stringent regulatory hurdles related to hazardous substances and environmental impact, although driving innovation in green alternatives, can also slow down product development and adoption. Competitive pressures from alternative encapsulation materials like silicones and polyurethanes, especially in niche applications, remain a concern. The high cost of research and development for novel formulations and the lengthy qualification processes for new materials in the semiconductor industry represent substantial barriers to entry and growth. The estimated impact of supply chain issues on market growth is approximately 1-2% reduction in CAGR during periods of significant disruption.

Emerging Opportunities in Epoxy Encapsulant Material

Emerging opportunities in the Epoxy Encapsulant Material sector lie in the development of advanced materials for next-generation semiconductor packaging technologies, such as chiplets and advanced 3D integration, which require encapsulation materials with exceptional thermal management and mechanical properties. The rapidly growing electric vehicle (EV) market presents a significant untapped opportunity, demanding robust encapsulation for power electronics and battery management systems. Furthermore, the expansion of 5G network infrastructure and the proliferation of IoT devices create a sustained demand for high-performance encapsulants. The increasing focus on sustainable and eco-friendly materials opens avenues for the development and adoption of bio-based or recycled epoxy formulations.

Growth Accelerators in the Epoxy Encapsulant Material Industry

Long-term growth in the Epoxy Encapsulant Material industry is significantly accelerated by continuous technological breakthroughs, such as the development of nano-enhanced epoxy composites that offer superior thermal conductivity and mechanical strength. Strategic partnerships between material manufacturers and semiconductor foundries are crucial for co-developing customized encapsulation solutions tailored to specific device requirements, driving innovation and market adoption. Market expansion strategies focusing on emerging economies and rapidly growing application sectors like automotive electronics and advanced medical devices will further amplify growth trajectories. Investments in R&D for high-performance, eco-friendly encapsulants will also be a key growth accelerator.

Key Players Shaping the Epoxy Encapsulant Material Market

- Sumitomo Bakelite

- Hitachi Chemical

- Chang Chun Group

- Hysol Huawei Electronics

- Panasonic

- Kyocera

- KCC

- Samsung SDI

- Eternal Materials

- Jiangsu Zhongpeng New Material

- Shin-Etsu Chemical

- Hexion

- Nepes

- Tianjin Kaihua Insulating Material

- HHCK

- Scienchem

- Beijing Sino-tech Electronic Material

Notable Milestones in Epoxy Encapsulant Material Sector

- 2019: Launch of new low-warpage epoxy molding compounds by Sumitomo Bakelite, catering to advanced semiconductor packaging.

- 2020: Hitachi Chemical (now Showa Denko Materials) introduces advanced green epoxy formulations compliant with stricter environmental regulations.

- 2021: Chang Chun Group expands its production capacity for epoxy encapsulants to meet rising demand from the electronics sector in Asia.

- 2022: Hysol Huawei Electronics develops high-thermal-conductivity epoxy for power semiconductor applications.

- 2023: Shin-Etsu Chemical announces significant investment in R&D for next-generation semiconductor encapsulation materials.

- 2024: Panasonic introduces ultra-low-stress epoxy encapsulants for sensitive optical components.

- 2025 (Estimated): Market anticipates new developments in mold-less encapsulation technologies utilizing advanced epoxy resins.

- 2026-2033 (Forecasted): Expectation of widespread adoption of bio-based epoxy encapsulants and materials for advanced packaging in AI and automotive applications.

In-Depth Epoxy Encapsulant Material Market Outlook

The future outlook for the Epoxy Encapsulant Material market is exceptionally promising, driven by synergistic growth accelerators. Continued technological breakthroughs in material science, leading to enhanced thermal management, electrical insulation, and mechanical robustness, will be pivotal. Strategic partnerships between leading material suppliers and semiconductor manufacturers will foster co-innovation, accelerating the development and adoption of specialized encapsulation solutions for cutting-edge applications like AI processors, advanced automotive electronics, and high-performance computing. Market expansion strategies targeting the burgeoning demand in electric vehicles and advanced telecommunications infrastructure will unlock significant growth potential. The increasing global focus on sustainability will further catalyze the demand for eco-friendly and green epoxy encapsulant materials, creating new market segments and driving innovation towards more environmentally conscious solutions. The overall market trajectory points towards sustained, robust growth fueled by these powerful accelerators.

Epoxy Encapsulant Material Segmentation

-

1. Application

- 1.1. Semiconductor Encapsulation

- 1.2. Electronic Components

-

2. Types

- 2.1. Normal Epoxy Molding Compound

- 2.2. Green Epoxy Molding Compound

Epoxy Encapsulant Material Segmentation By Geography

-

1. North America

- 1.1. United States

- 1.2. Canada

- 1.3. Mexico

-

2. South America

- 2.1. Brazil

- 2.2. Argentina

- 2.3. Rest of South America

-

3. Europe

- 3.1. United Kingdom

- 3.2. Germany

- 3.3. France

- 3.4. Italy

- 3.5. Spain

- 3.6. Russia

- 3.7. Benelux

- 3.8. Nordics

- 3.9. Rest of Europe

-

4. Middle East & Africa

- 4.1. Turkey

- 4.2. Israel

- 4.3. GCC

- 4.4. North Africa

- 4.5. South Africa

- 4.6. Rest of Middle East & Africa

-

5. Asia Pacific

- 5.1. China

- 5.2. India

- 5.3. Japan

- 5.4. South Korea

- 5.5. ASEAN

- 5.6. Oceania

- 5.7. Rest of Asia Pacific

Epoxy Encapsulant Material REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.3. Market Restrains

- 3.4. Market Trends

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global Epoxy Encapsulant Material Analysis, Insights and Forecast, 2019-2031

- 5.1. Market Analysis, Insights and Forecast - by Application

- 5.1.1. Semiconductor Encapsulation

- 5.1.2. Electronic Components

- 5.2. Market Analysis, Insights and Forecast - by Types

- 5.2.1. Normal Epoxy Molding Compound

- 5.2.2. Green Epoxy Molding Compound

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. North America

- 5.3.2. South America

- 5.3.3. Europe

- 5.3.4. Middle East & Africa

- 5.3.5. Asia Pacific

- 5.1. Market Analysis, Insights and Forecast - by Application

- 6. North America Epoxy Encapsulant Material Analysis, Insights and Forecast, 2019-2031

- 6.1. Market Analysis, Insights and Forecast - by Application

- 6.1.1. Semiconductor Encapsulation

- 6.1.2. Electronic Components

- 6.2. Market Analysis, Insights and Forecast - by Types

- 6.2.1. Normal Epoxy Molding Compound

- 6.2.2. Green Epoxy Molding Compound

- 6.1. Market Analysis, Insights and Forecast - by Application

- 7. South America Epoxy Encapsulant Material Analysis, Insights and Forecast, 2019-2031

- 7.1. Market Analysis, Insights and Forecast - by Application

- 7.1.1. Semiconductor Encapsulation

- 7.1.2. Electronic Components

- 7.2. Market Analysis, Insights and Forecast - by Types

- 7.2.1. Normal Epoxy Molding Compound

- 7.2.2. Green Epoxy Molding Compound

- 7.1. Market Analysis, Insights and Forecast - by Application

- 8. Europe Epoxy Encapsulant Material Analysis, Insights and Forecast, 2019-2031

- 8.1. Market Analysis, Insights and Forecast - by Application

- 8.1.1. Semiconductor Encapsulation

- 8.1.2. Electronic Components

- 8.2. Market Analysis, Insights and Forecast - by Types

- 8.2.1. Normal Epoxy Molding Compound

- 8.2.2. Green Epoxy Molding Compound

- 8.1. Market Analysis, Insights and Forecast - by Application

- 9. Middle East & Africa Epoxy Encapsulant Material Analysis, Insights and Forecast, 2019-2031

- 9.1. Market Analysis, Insights and Forecast - by Application

- 9.1.1. Semiconductor Encapsulation

- 9.1.2. Electronic Components

- 9.2. Market Analysis, Insights and Forecast - by Types

- 9.2.1. Normal Epoxy Molding Compound

- 9.2.2. Green Epoxy Molding Compound

- 9.1. Market Analysis, Insights and Forecast - by Application

- 10. Asia Pacific Epoxy Encapsulant Material Analysis, Insights and Forecast, 2019-2031

- 10.1. Market Analysis, Insights and Forecast - by Application

- 10.1.1. Semiconductor Encapsulation

- 10.1.2. Electronic Components

- 10.2. Market Analysis, Insights and Forecast - by Types

- 10.2.1. Normal Epoxy Molding Compound

- 10.2.2. Green Epoxy Molding Compound

- 10.1. Market Analysis, Insights and Forecast - by Application

- 11. Competitive Analysis

- 11.1. Global Market Share Analysis 2024

- 11.2. Company Profiles

- 11.2.1 Sumitomo Bakelite

- 11.2.1.1. Overview

- 11.2.1.2. Products

- 11.2.1.3. SWOT Analysis

- 11.2.1.4. Recent Developments

- 11.2.1.5. Financials (Based on Availability)

- 11.2.2 Hitachi Chemical

- 11.2.2.1. Overview

- 11.2.2.2. Products

- 11.2.2.3. SWOT Analysis

- 11.2.2.4. Recent Developments

- 11.2.2.5. Financials (Based on Availability)

- 11.2.3 Chang Chun Group

- 11.2.3.1. Overview

- 11.2.3.2. Products

- 11.2.3.3. SWOT Analysis

- 11.2.3.4. Recent Developments

- 11.2.3.5. Financials (Based on Availability)

- 11.2.4 Hysol Huawei Electronics

- 11.2.4.1. Overview

- 11.2.4.2. Products

- 11.2.4.3. SWOT Analysis

- 11.2.4.4. Recent Developments

- 11.2.4.5. Financials (Based on Availability)

- 11.2.5 Panasonic

- 11.2.5.1. Overview

- 11.2.5.2. Products

- 11.2.5.3. SWOT Analysis

- 11.2.5.4. Recent Developments

- 11.2.5.5. Financials (Based on Availability)

- 11.2.6 Kyocera

- 11.2.6.1. Overview

- 11.2.6.2. Products

- 11.2.6.3. SWOT Analysis

- 11.2.6.4. Recent Developments

- 11.2.6.5. Financials (Based on Availability)

- 11.2.7 KCC

- 11.2.7.1. Overview

- 11.2.7.2. Products

- 11.2.7.3. SWOT Analysis

- 11.2.7.4. Recent Developments

- 11.2.7.5. Financials (Based on Availability)

- 11.2.8 Samsung SDI

- 11.2.8.1. Overview

- 11.2.8.2. Products

- 11.2.8.3. SWOT Analysis

- 11.2.8.4. Recent Developments

- 11.2.8.5. Financials (Based on Availability)

- 11.2.9 Eternal Materials

- 11.2.9.1. Overview

- 11.2.9.2. Products

- 11.2.9.3. SWOT Analysis

- 11.2.9.4. Recent Developments

- 11.2.9.5. Financials (Based on Availability)

- 11.2.10 Jiangsu Zhongpeng New Material

- 11.2.10.1. Overview

- 11.2.10.2. Products

- 11.2.10.3. SWOT Analysis

- 11.2.10.4. Recent Developments

- 11.2.10.5. Financials (Based on Availability)

- 11.2.11 Shin-Etsu Chemical

- 11.2.11.1. Overview

- 11.2.11.2. Products

- 11.2.11.3. SWOT Analysis

- 11.2.11.4. Recent Developments

- 11.2.11.5. Financials (Based on Availability)

- 11.2.12 Hexion

- 11.2.12.1. Overview

- 11.2.12.2. Products

- 11.2.12.3. SWOT Analysis

- 11.2.12.4. Recent Developments

- 11.2.12.5. Financials (Based on Availability)

- 11.2.13 Nepes

- 11.2.13.1. Overview

- 11.2.13.2. Products

- 11.2.13.3. SWOT Analysis

- 11.2.13.4. Recent Developments

- 11.2.13.5. Financials (Based on Availability)

- 11.2.14 Tianjin Kaihua Insulating Material

- 11.2.14.1. Overview

- 11.2.14.2. Products

- 11.2.14.3. SWOT Analysis

- 11.2.14.4. Recent Developments

- 11.2.14.5. Financials (Based on Availability)

- 11.2.15 HHCK

- 11.2.15.1. Overview

- 11.2.15.2. Products

- 11.2.15.3. SWOT Analysis

- 11.2.15.4. Recent Developments

- 11.2.15.5. Financials (Based on Availability)

- 11.2.16 Scienchem

- 11.2.16.1. Overview

- 11.2.16.2. Products

- 11.2.16.3. SWOT Analysis

- 11.2.16.4. Recent Developments

- 11.2.16.5. Financials (Based on Availability)

- 11.2.17 Beijing Sino-tech Electronic Material

- 11.2.17.1. Overview

- 11.2.17.2. Products

- 11.2.17.3. SWOT Analysis

- 11.2.17.4. Recent Developments

- 11.2.17.5. Financials (Based on Availability)

- 11.2.1 Sumitomo Bakelite

List of Figures

- Figure 1: Global Epoxy Encapsulant Material Revenue Breakdown (million, %) by Region 2024 & 2032

- Figure 2: North America Epoxy Encapsulant Material Revenue (million), by Application 2024 & 2032

- Figure 3: North America Epoxy Encapsulant Material Revenue Share (%), by Application 2024 & 2032

- Figure 4: North America Epoxy Encapsulant Material Revenue (million), by Types 2024 & 2032

- Figure 5: North America Epoxy Encapsulant Material Revenue Share (%), by Types 2024 & 2032

- Figure 6: North America Epoxy Encapsulant Material Revenue (million), by Country 2024 & 2032

- Figure 7: North America Epoxy Encapsulant Material Revenue Share (%), by Country 2024 & 2032

- Figure 8: South America Epoxy Encapsulant Material Revenue (million), by Application 2024 & 2032

- Figure 9: South America Epoxy Encapsulant Material Revenue Share (%), by Application 2024 & 2032

- Figure 10: South America Epoxy Encapsulant Material Revenue (million), by Types 2024 & 2032

- Figure 11: South America Epoxy Encapsulant Material Revenue Share (%), by Types 2024 & 2032

- Figure 12: South America Epoxy Encapsulant Material Revenue (million), by Country 2024 & 2032

- Figure 13: South America Epoxy Encapsulant Material Revenue Share (%), by Country 2024 & 2032

- Figure 14: Europe Epoxy Encapsulant Material Revenue (million), by Application 2024 & 2032

- Figure 15: Europe Epoxy Encapsulant Material Revenue Share (%), by Application 2024 & 2032

- Figure 16: Europe Epoxy Encapsulant Material Revenue (million), by Types 2024 & 2032

- Figure 17: Europe Epoxy Encapsulant Material Revenue Share (%), by Types 2024 & 2032

- Figure 18: Europe Epoxy Encapsulant Material Revenue (million), by Country 2024 & 2032

- Figure 19: Europe Epoxy Encapsulant Material Revenue Share (%), by Country 2024 & 2032

- Figure 20: Middle East & Africa Epoxy Encapsulant Material Revenue (million), by Application 2024 & 2032

- Figure 21: Middle East & Africa Epoxy Encapsulant Material Revenue Share (%), by Application 2024 & 2032

- Figure 22: Middle East & Africa Epoxy Encapsulant Material Revenue (million), by Types 2024 & 2032

- Figure 23: Middle East & Africa Epoxy Encapsulant Material Revenue Share (%), by Types 2024 & 2032

- Figure 24: Middle East & Africa Epoxy Encapsulant Material Revenue (million), by Country 2024 & 2032

- Figure 25: Middle East & Africa Epoxy Encapsulant Material Revenue Share (%), by Country 2024 & 2032

- Figure 26: Asia Pacific Epoxy Encapsulant Material Revenue (million), by Application 2024 & 2032

- Figure 27: Asia Pacific Epoxy Encapsulant Material Revenue Share (%), by Application 2024 & 2032

- Figure 28: Asia Pacific Epoxy Encapsulant Material Revenue (million), by Types 2024 & 2032

- Figure 29: Asia Pacific Epoxy Encapsulant Material Revenue Share (%), by Types 2024 & 2032

- Figure 30: Asia Pacific Epoxy Encapsulant Material Revenue (million), by Country 2024 & 2032

- Figure 31: Asia Pacific Epoxy Encapsulant Material Revenue Share (%), by Country 2024 & 2032

List of Tables

- Table 1: Global Epoxy Encapsulant Material Revenue million Forecast, by Region 2019 & 2032

- Table 2: Global Epoxy Encapsulant Material Revenue million Forecast, by Application 2019 & 2032

- Table 3: Global Epoxy Encapsulant Material Revenue million Forecast, by Types 2019 & 2032

- Table 4: Global Epoxy Encapsulant Material Revenue million Forecast, by Region 2019 & 2032

- Table 5: Global Epoxy Encapsulant Material Revenue million Forecast, by Application 2019 & 2032

- Table 6: Global Epoxy Encapsulant Material Revenue million Forecast, by Types 2019 & 2032

- Table 7: Global Epoxy Encapsulant Material Revenue million Forecast, by Country 2019 & 2032

- Table 8: United States Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 9: Canada Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 10: Mexico Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 11: Global Epoxy Encapsulant Material Revenue million Forecast, by Application 2019 & 2032

- Table 12: Global Epoxy Encapsulant Material Revenue million Forecast, by Types 2019 & 2032

- Table 13: Global Epoxy Encapsulant Material Revenue million Forecast, by Country 2019 & 2032

- Table 14: Brazil Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 15: Argentina Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 16: Rest of South America Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 17: Global Epoxy Encapsulant Material Revenue million Forecast, by Application 2019 & 2032

- Table 18: Global Epoxy Encapsulant Material Revenue million Forecast, by Types 2019 & 2032

- Table 19: Global Epoxy Encapsulant Material Revenue million Forecast, by Country 2019 & 2032

- Table 20: United Kingdom Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 21: Germany Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 22: France Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 23: Italy Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 24: Spain Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 25: Russia Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 26: Benelux Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 27: Nordics Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 28: Rest of Europe Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 29: Global Epoxy Encapsulant Material Revenue million Forecast, by Application 2019 & 2032

- Table 30: Global Epoxy Encapsulant Material Revenue million Forecast, by Types 2019 & 2032

- Table 31: Global Epoxy Encapsulant Material Revenue million Forecast, by Country 2019 & 2032

- Table 32: Turkey Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 33: Israel Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 34: GCC Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 35: North Africa Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 36: South Africa Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 37: Rest of Middle East & Africa Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 38: Global Epoxy Encapsulant Material Revenue million Forecast, by Application 2019 & 2032

- Table 39: Global Epoxy Encapsulant Material Revenue million Forecast, by Types 2019 & 2032

- Table 40: Global Epoxy Encapsulant Material Revenue million Forecast, by Country 2019 & 2032

- Table 41: China Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 42: India Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 43: Japan Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 44: South Korea Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 45: ASEAN Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 46: Oceania Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 47: Rest of Asia Pacific Epoxy Encapsulant Material Revenue (million) Forecast, by Application 2019 & 2032

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Epoxy Encapsulant Material?

The projected CAGR is approximately XX%.

2. Which companies are prominent players in the Epoxy Encapsulant Material?

Key companies in the market include Sumitomo Bakelite, Hitachi Chemical, Chang Chun Group, Hysol Huawei Electronics, Panasonic, Kyocera, KCC, Samsung SDI, Eternal Materials, Jiangsu Zhongpeng New Material, Shin-Etsu Chemical, Hexion, Nepes, Tianjin Kaihua Insulating Material, HHCK, Scienchem, Beijing Sino-tech Electronic Material.

3. What are the main segments of the Epoxy Encapsulant Material?

The market segments include Application, Types.

4. Can you provide details about the market size?

The market size is estimated to be USD XXX million as of 2022.

5. What are some drivers contributing to market growth?

N/A

6. What are the notable trends driving market growth?

N/A

7. Are there any restraints impacting market growth?

N/A

8. Can you provide examples of recent developments in the market?

N/A

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4900.00, USD 7350.00, and USD 9800.00 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in million.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Epoxy Encapsulant Material," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Epoxy Encapsulant Material report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Epoxy Encapsulant Material?

To stay informed about further developments, trends, and reports in the Epoxy Encapsulant Material, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence