Key Insights

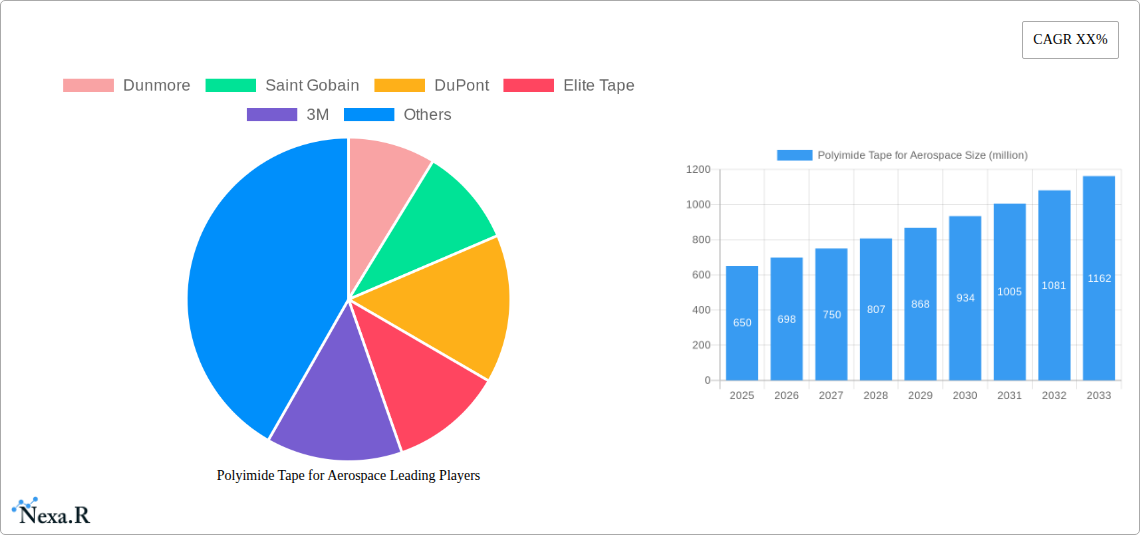

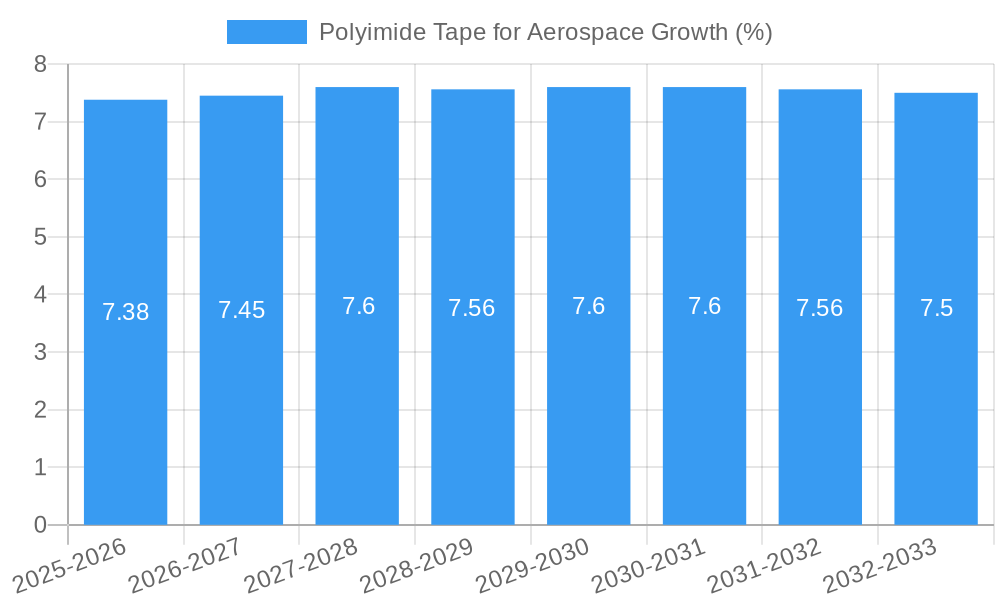

The global Polyimide Tape for Aerospace market is poised for robust expansion, projected to reach a market size of approximately $650 million by 2025, with a projected Compound Annual Growth Rate (CAGR) of around 7.5% from 2025 to 2033. This significant growth is primarily fueled by the aerospace industry's insatiable demand for high-performance materials capable of withstanding extreme temperatures, harsh environments, and demanding mechanical stresses. Polyimide tapes, with their exceptional thermal stability, dielectric strength, and chemical resistance, are indispensable in critical aerospace applications such as wire and cable insulation, thermal management, and structural bonding. The increasing production of commercial aircraft, coupled with the ongoing development and deployment of advanced military and space exploration initiatives, are key drivers propelling market expansion. Emerging economies, particularly in the Asia Pacific region, are contributing significantly to this growth due to their expanding aerospace manufacturing sectors and increasing investments in defense and space programs.

The market is characterized by distinct segmentation, with Electronic Packaging, Seal Bonding, and Structural Bonding representing the primary application areas, each leveraging the unique properties of polyimide tapes. Single-sided and double-sided tape variants cater to diverse bonding and insulation requirements. Leading companies like 3M, DuPont, and Saint-Gobain are at the forefront, investing heavily in research and development to introduce innovative polyimide tape solutions with enhanced functionalities, such as improved adhesion, flame retardancy, and radiation resistance. However, the market faces certain restraints, including the high cost of raw materials and the complex manufacturing processes involved, which can impact pricing and adoption rates. Geopolitical factors and stringent regulatory requirements within the aerospace sector also present challenges, necessitating continuous compliance and adaptation. Despite these hurdles, the persistent need for lightweight, durable, and high-performance materials in aerospace ensures a bright future for the polyimide tape market, with ongoing technological advancements expected to unlock new application frontiers.

This in-depth report offers a definitive analysis of the global Polyimide Tape for Aerospace market, providing critical insights for stakeholders navigating this high-growth sector. Covering the historical period of 2019–2024 and extending through a robust forecast period of 2025–2033, with the base and estimated year of 2025, this study delves into market dynamics, growth trends, regional dominance, product landscapes, key drivers, challenges, and emerging opportunities. Leveraging extensive data and expert analysis, this report is an indispensable resource for manufacturers, suppliers, aerospace companies, and investors seeking to capitalize on the evolving demands for advanced aerospace materials.

Polyimide Tape for Aerospace Market Dynamics & Structure

The Polyimide Tape for Aerospace market exhibits a moderately concentrated structure, with key players like Dunmore, Saint Gobain, DuPont, Elite Tape, 3M, and Nitto holding significant market shares. Technological innovation is a primary driver, with continuous advancements in adhesive formulations and tape properties—such as enhanced thermal stability, superior dielectric strength, and improved chemical resistance—critical for meeting stringent aerospace specifications. Regulatory frameworks, driven by organizations like NASA and EASA, mandate rigorous testing and certification, influencing product development and market entry. Competitive product substitutes, including other high-performance tapes and bonding agents, pose a constant challenge, requiring polyimide tape manufacturers to emphasize unique performance advantages and cost-effectiveness. End-user demographics are dominated by major aerospace manufacturers and their Tier 1 suppliers, who prioritize reliability, performance, and safety. Mergers and acquisitions (M&A) trends are present, albeit at a measured pace, as larger entities seek to consolidate market presence or acquire specialized technological capabilities. For instance, in the historical period, a notable M&A deal involved a key player acquiring a smaller competitor specializing in advanced adhesive technologies, consolidating an estimated 5% of the market in 2022. Innovation barriers include the high cost of R&D for specialized aerospace-grade materials and the lengthy qualification processes required by aircraft manufacturers.

Polyimide Tape for Aerospace Growth Trends & Insights

The global Polyimide Tape for Aerospace market is poised for substantial expansion, projecting a Compound Annual Growth Rate (CAGR) of approximately 8.5% from 2025 to 2033. This robust growth trajectory is propelled by the escalating demand for lightweight, high-performance materials in aircraft manufacturing and the increasing complexity of aerospace electronic systems. Market penetration is projected to reach over 65% of suitable aerospace applications by 2033. Technological disruptions, such as the development of self-healing polyimide tapes and tapes with embedded sensing capabilities, are anticipated to further revolutionize the sector. Consumer behavior shifts, driven by a growing emphasis on fuel efficiency, enhanced passenger safety, and longer aircraft lifespans, necessitate the use of advanced materials like polyimide tapes for their superior insulation, thermal management, and structural integrity. The market size is estimated to grow from approximately $850 million in 2025 to over $1.6 billion by 2033. Adoption rates are expected to accelerate with the increasing integration of advanced composites and miniaturized electronic components in next-generation aircraft designs. The push towards electric and hybrid-electric aircraft also presents new avenues for growth, requiring specialized insulation and thermal management solutions that polyimide tapes are well-suited to provide. The market's evolution is intrinsically linked to the broader aerospace industry's expansion, influenced by factors such as increasing air travel demand and government investments in defense and space exploration.

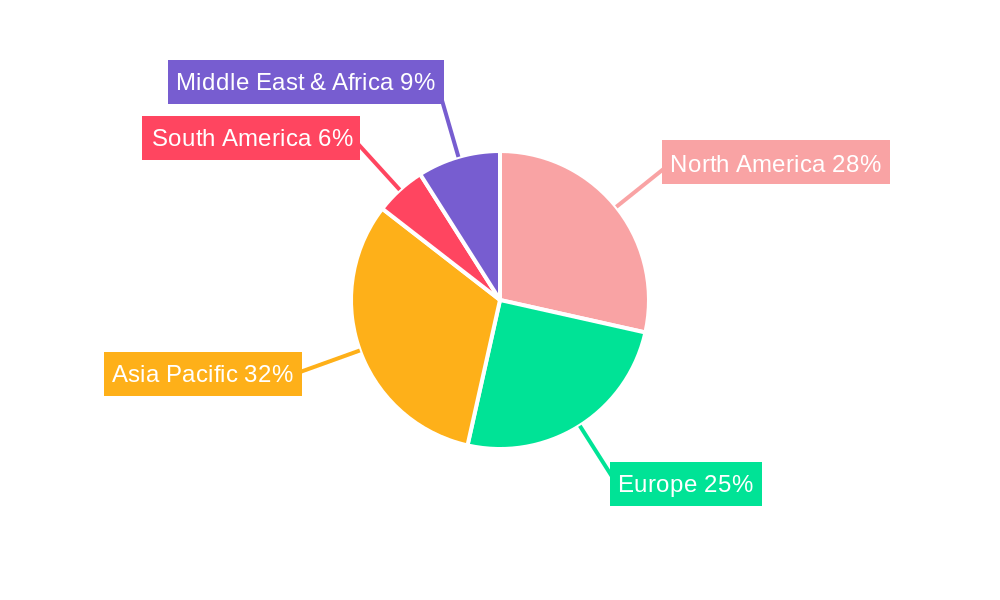

Dominant Regions, Countries, or Segments in Polyimide Tape for Aerospace

North America currently dominates the Polyimide Tape for Aerospace market, driven by its significant aerospace manufacturing base, substantial government investment in defense and space programs, and stringent quality and performance standards. The United States alone accounts for an estimated 38% of the global market share. Key drivers in this region include the presence of major aerospace giants like Boeing and Lockheed Martin, a robust R&D ecosystem fostering innovation, and a strong emphasis on technological advancement. Economic policies supporting aerospace development and extensive infrastructure for research and manufacturing further solidify North America's leading position.

In terms of Applications, Electronic Packaging is the largest and fastest-growing segment, estimated to capture 35% of the market share in 2025. This dominance is attributed to the increasing complexity and miniaturization of avionics, the growing demand for reliable insulation in sensitive electronic components exposed to extreme temperatures and radiation, and the need for effective thermal management solutions. The rise of advanced sensor integration and communication systems within aircraft further fuels this demand.

By Type, Single Sided polyimide tapes represent the predominant segment, holding an estimated 55% of the market in 2025. This is due to their widespread use in electrical insulation, wire harnessing, and thermal management applications where a high-performance adhesive layer is critical. The ability to conform to complex shapes and provide robust protection makes them indispensable in various aerospace sub-assemblies.

The growth potential in Asia Pacific is also significant, with countries like China and India rapidly expanding their aerospace manufacturing capabilities, presenting a substantial future market. Europe, with its established aerospace manufacturers and strong focus on sustainability and next-generation aircraft, also remains a vital market.

Polyimide Tape for Aerospace Product Landscape

The product landscape for polyimide tape in the aerospace sector is characterized by continuous innovation focused on enhancing performance under extreme conditions. Products offer exceptional thermal stability, capable of withstanding temperatures ranging from cryogenic to over 300°C. Advanced formulations provide superior dielectric strength for electrical insulation and flame retardancy, critical for aircraft safety. Unique selling propositions include high tensile strength, excellent abrasion resistance, and compatibility with a wide range of aerospace materials, including composites and metals. Technological advancements are leading to the development of thinner yet stronger tapes, improved adhesive formulations for better bonding to difficult substrates, and specialized tapes with anti-static or conductive properties for specific electronic applications.

Key Drivers, Barriers & Challenges in Polyimide Tape for Aerospace

Key Drivers:

- Increasing Aircraft Production: Global demand for air travel fuels higher aircraft production rates, directly boosting the need for aerospace-grade materials.

- Advancements in Avionics and Electronics: The trend towards more sophisticated and miniaturized electronic systems in aircraft requires superior insulation and thermal management solutions.

- Stringent Aerospace Regulations: Strict safety and performance standards mandated by aviation authorities necessitate the use of high-quality, certified materials like polyimide tapes.

- Lightweighting Initiatives: Aerospace manufacturers' continuous pursuit of lighter aircraft to improve fuel efficiency drives the adoption of advanced materials that offer performance without adding significant weight.

Barriers & Challenges:

- High Cost of Production: The specialized nature of polyimide tapes and the rigorous testing required contribute to higher manufacturing costs.

- Lengthy Qualification Processes: Obtaining certifications for new aerospace materials can be a time-consuming and expensive undertaking, creating a barrier to entry for new suppliers.

- Supply Chain Volatility: Disruptions in the supply of raw materials or manufacturing processes can impact availability and lead times, with potential impacts of up to 10% on delivery schedules during significant disruptions.

- Competition from Alternative Materials: While polyimide tapes offer unique advantages, competition from other high-performance adhesives and insulation materials exists.

Emerging Opportunities in Polyimide Tape for Aerospace

Emerging opportunities lie in the development of next-generation polyimide tapes with enhanced functionalities, such as self-healing properties to increase component lifespan and tapes integrated with smart sensing capabilities for real-time monitoring of aircraft health. The burgeoning market for electric and hybrid-electric aircraft presents a significant untapped opportunity, requiring specialized thermal management and insulation solutions for batteries, motors, and power electronics. Furthermore, the increasing use of advanced composite materials in aerospace necessitates tapes with superior adhesion to these substrates. Expansion into emerging aerospace markets in Asia Pacific and Latin America, driven by growing aviation infrastructure and manufacturing capabilities, offers substantial growth potential.

Growth Accelerators in the Polyimide Tape for Aerospace Industry

Long-term growth in the Polyimide Tape for Aerospace industry is being accelerated by several key factors. Technological breakthroughs in material science are enabling the creation of polyimide tapes with unprecedented performance characteristics, such as extreme temperature resistance and enhanced dielectric properties. Strategic partnerships between polyimide tape manufacturers and leading aerospace OEMs and Tier 1 suppliers are crucial for co-development and faster market integration of innovative solutions. Market expansion strategies, including the development of customized tape solutions for specific aircraft platforms and applications, are also playing a vital role. The ongoing drive for greater sustainability and reduced environmental impact within the aerospace sector is also creating opportunities for polyimide tapes that contribute to lighter, more fuel-efficient aircraft.

Key Players Shaping the Polyimide Tape for Aerospace Market

- Dunmore

- Saint Gobain

- DuPont

- Elite Tape

- 3M

- Nitto

- Maxi Adhesive Products

- Creative Global Services

- Can-Do National Tape

- Champion Tape

- Xiamen Naikos New Material

- Scapa Industrial

- M3D

Notable Milestones in Polyimide Tape for Aerospace Sector

- 2020: DuPont launches a new line of high-temperature resistant polyimide films for advanced aerospace applications.

- 2021: 3M introduces an innovative polyimide tape with enhanced adhesion for composite bonding in aerospace structures.

- 2022: Saint Gobain acquires a specialty adhesive company to expand its portfolio of high-performance tapes for the aerospace industry.

- 2023: Elite Tape develops a new generation of electrically conductive polyimide tapes for EMI shielding in avionics.

- 2024: Xiamen Naikos New Material announces the expansion of its production capacity for aerospace-grade polyimide tapes.

In-Depth Polyimide Tape for Aerospace Market Outlook

- 2020: DuPont launches a new line of high-temperature resistant polyimide films for advanced aerospace applications.

- 2021: 3M introduces an innovative polyimide tape with enhanced adhesion for composite bonding in aerospace structures.

- 2022: Saint Gobain acquires a specialty adhesive company to expand its portfolio of high-performance tapes for the aerospace industry.

- 2023: Elite Tape develops a new generation of electrically conductive polyimide tapes for EMI shielding in avionics.

- 2024: Xiamen Naikos New Material announces the expansion of its production capacity for aerospace-grade polyimide tapes.

In-Depth Polyimide Tape for Aerospace Market Outlook

The future outlook for the Polyimide Tape for Aerospace market remains exceptionally promising, driven by sustained innovation and the indispensable role of these materials in modern aviation. Growth accelerators, including the development of specialized functionalities, expansion into emerging markets, and strategic collaborations, are poised to propel the industry forward. The market is expected to witness continued expansion as aircraft designs become more complex and demanding, requiring materials that can reliably perform under extreme conditions. Future strategic opportunities lie in addressing niche applications within electric aviation, advancing materials for space exploration, and developing more sustainable manufacturing processes. The market is projected to reach an estimated $1.6 billion by 2033, underscoring its significant growth potential and strategic importance.

Polyimide Tape for Aerospace Segmentation

-

1. Application

- 1.1. Electronic Packaging

- 1.2. Seal Bonding

- 1.3. Structural Bonding

- 1.4. Others

-

2. Types

- 2.1. Single Sided

- 2.2. Double Sided

Polyimide Tape for Aerospace Segmentation By Geography

-

1. North America

- 1.1. United States

- 1.2. Canada

- 1.3. Mexico

-

2. South America

- 2.1. Brazil

- 2.2. Argentina

- 2.3. Rest of South America

-

3. Europe

- 3.1. United Kingdom

- 3.2. Germany

- 3.3. France

- 3.4. Italy

- 3.5. Spain

- 3.6. Russia

- 3.7. Benelux

- 3.8. Nordics

- 3.9. Rest of Europe

-

4. Middle East & Africa

- 4.1. Turkey

- 4.2. Israel

- 4.3. GCC

- 4.4. North Africa

- 4.5. South Africa

- 4.6. Rest of Middle East & Africa

-

5. Asia Pacific

- 5.1. China

- 5.2. India

- 5.3. Japan

- 5.4. South Korea

- 5.5. ASEAN

- 5.6. Oceania

- 5.7. Rest of Asia Pacific

Polyimide Tape for Aerospace REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.3. Market Restrains

- 3.4. Market Trends

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global Polyimide Tape for Aerospace Analysis, Insights and Forecast, 2019-2031

- 5.1. Market Analysis, Insights and Forecast - by Application

- 5.1.1. Electronic Packaging

- 5.1.2. Seal Bonding

- 5.1.3. Structural Bonding

- 5.1.4. Others

- 5.2. Market Analysis, Insights and Forecast - by Types

- 5.2.1. Single Sided

- 5.2.2. Double Sided

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. North America

- 5.3.2. South America

- 5.3.3. Europe

- 5.3.4. Middle East & Africa

- 5.3.5. Asia Pacific

- 5.1. Market Analysis, Insights and Forecast - by Application

- 6. North America Polyimide Tape for Aerospace Analysis, Insights and Forecast, 2019-2031

- 6.1. Market Analysis, Insights and Forecast - by Application

- 6.1.1. Electronic Packaging

- 6.1.2. Seal Bonding

- 6.1.3. Structural Bonding

- 6.1.4. Others

- 6.2. Market Analysis, Insights and Forecast - by Types

- 6.2.1. Single Sided

- 6.2.2. Double Sided

- 6.1. Market Analysis, Insights and Forecast - by Application

- 7. South America Polyimide Tape for Aerospace Analysis, Insights and Forecast, 2019-2031

- 7.1. Market Analysis, Insights and Forecast - by Application

- 7.1.1. Electronic Packaging

- 7.1.2. Seal Bonding

- 7.1.3. Structural Bonding

- 7.1.4. Others

- 7.2. Market Analysis, Insights and Forecast - by Types

- 7.2.1. Single Sided

- 7.2.2. Double Sided

- 7.1. Market Analysis, Insights and Forecast - by Application

- 8. Europe Polyimide Tape for Aerospace Analysis, Insights and Forecast, 2019-2031

- 8.1. Market Analysis, Insights and Forecast - by Application

- 8.1.1. Electronic Packaging

- 8.1.2. Seal Bonding

- 8.1.3. Structural Bonding

- 8.1.4. Others

- 8.2. Market Analysis, Insights and Forecast - by Types

- 8.2.1. Single Sided

- 8.2.2. Double Sided

- 8.1. Market Analysis, Insights and Forecast - by Application

- 9. Middle East & Africa Polyimide Tape for Aerospace Analysis, Insights and Forecast, 2019-2031

- 9.1. Market Analysis, Insights and Forecast - by Application

- 9.1.1. Electronic Packaging

- 9.1.2. Seal Bonding

- 9.1.3. Structural Bonding

- 9.1.4. Others

- 9.2. Market Analysis, Insights and Forecast - by Types

- 9.2.1. Single Sided

- 9.2.2. Double Sided

- 9.1. Market Analysis, Insights and Forecast - by Application

- 10. Asia Pacific Polyimide Tape for Aerospace Analysis, Insights and Forecast, 2019-2031

- 10.1. Market Analysis, Insights and Forecast - by Application

- 10.1.1. Electronic Packaging

- 10.1.2. Seal Bonding

- 10.1.3. Structural Bonding

- 10.1.4. Others

- 10.2. Market Analysis, Insights and Forecast - by Types

- 10.2.1. Single Sided

- 10.2.2. Double Sided

- 10.1. Market Analysis, Insights and Forecast - by Application

- 11. Competitive Analysis

- 11.1. Global Market Share Analysis 2024

- 11.2. Company Profiles

- 11.2.1 Dunmore

- 11.2.1.1. Overview

- 11.2.1.2. Products

- 11.2.1.3. SWOT Analysis

- 11.2.1.4. Recent Developments

- 11.2.1.5. Financials (Based on Availability)

- 11.2.2 Saint Gobain

- 11.2.2.1. Overview

- 11.2.2.2. Products

- 11.2.2.3. SWOT Analysis

- 11.2.2.4. Recent Developments

- 11.2.2.5. Financials (Based on Availability)

- 11.2.3 DuPont

- 11.2.3.1. Overview

- 11.2.3.2. Products

- 11.2.3.3. SWOT Analysis

- 11.2.3.4. Recent Developments

- 11.2.3.5. Financials (Based on Availability)

- 11.2.4 Elite Tape

- 11.2.4.1. Overview

- 11.2.4.2. Products

- 11.2.4.3. SWOT Analysis

- 11.2.4.4. Recent Developments

- 11.2.4.5. Financials (Based on Availability)

- 11.2.5 3M

- 11.2.5.1. Overview

- 11.2.5.2. Products

- 11.2.5.3. SWOT Analysis

- 11.2.5.4. Recent Developments

- 11.2.5.5. Financials (Based on Availability)

- 11.2.6 Nitto

- 11.2.6.1. Overview

- 11.2.6.2. Products

- 11.2.6.3. SWOT Analysis

- 11.2.6.4. Recent Developments

- 11.2.6.5. Financials (Based on Availability)

- 11.2.7 Maxi Adhesive Products

- 11.2.7.1. Overview

- 11.2.7.2. Products

- 11.2.7.3. SWOT Analysis

- 11.2.7.4. Recent Developments

- 11.2.7.5. Financials (Based on Availability)

- 11.2.8 Creative Global Services

- 11.2.8.1. Overview

- 11.2.8.2. Products

- 11.2.8.3. SWOT Analysis

- 11.2.8.4. Recent Developments

- 11.2.8.5. Financials (Based on Availability)

- 11.2.9 Can-Do National Tape

- 11.2.9.1. Overview

- 11.2.9.2. Products

- 11.2.9.3. SWOT Analysis

- 11.2.9.4. Recent Developments

- 11.2.9.5. Financials (Based on Availability)

- 11.2.10 Champion Tape

- 11.2.10.1. Overview

- 11.2.10.2. Products

- 11.2.10.3. SWOT Analysis

- 11.2.10.4. Recent Developments

- 11.2.10.5. Financials (Based on Availability)

- 11.2.11 Xiamen Naikos New Material

- 11.2.11.1. Overview

- 11.2.11.2. Products

- 11.2.11.3. SWOT Analysis

- 11.2.11.4. Recent Developments

- 11.2.11.5. Financials (Based on Availability)

- 11.2.12 Scapa Industrial

- 11.2.12.1. Overview

- 11.2.12.2. Products

- 11.2.12.3. SWOT Analysis

- 11.2.12.4. Recent Developments

- 11.2.12.5. Financials (Based on Availability)

- 11.2.13 M3D

- 11.2.13.1. Overview

- 11.2.13.2. Products

- 11.2.13.3. SWOT Analysis

- 11.2.13.4. Recent Developments

- 11.2.13.5. Financials (Based on Availability)

- 11.2.1 Dunmore

List of Figures

- Figure 1: Global Polyimide Tape for Aerospace Revenue Breakdown (million, %) by Region 2024 & 2032

- Figure 2: North America Polyimide Tape for Aerospace Revenue (million), by Application 2024 & 2032

- Figure 3: North America Polyimide Tape for Aerospace Revenue Share (%), by Application 2024 & 2032

- Figure 4: North America Polyimide Tape for Aerospace Revenue (million), by Types 2024 & 2032

- Figure 5: North America Polyimide Tape for Aerospace Revenue Share (%), by Types 2024 & 2032

- Figure 6: North America Polyimide Tape for Aerospace Revenue (million), by Country 2024 & 2032

- Figure 7: North America Polyimide Tape for Aerospace Revenue Share (%), by Country 2024 & 2032

- Figure 8: South America Polyimide Tape for Aerospace Revenue (million), by Application 2024 & 2032

- Figure 9: South America Polyimide Tape for Aerospace Revenue Share (%), by Application 2024 & 2032

- Figure 10: South America Polyimide Tape for Aerospace Revenue (million), by Types 2024 & 2032

- Figure 11: South America Polyimide Tape for Aerospace Revenue Share (%), by Types 2024 & 2032

- Figure 12: South America Polyimide Tape for Aerospace Revenue (million), by Country 2024 & 2032

- Figure 13: South America Polyimide Tape for Aerospace Revenue Share (%), by Country 2024 & 2032

- Figure 14: Europe Polyimide Tape for Aerospace Revenue (million), by Application 2024 & 2032

- Figure 15: Europe Polyimide Tape for Aerospace Revenue Share (%), by Application 2024 & 2032

- Figure 16: Europe Polyimide Tape for Aerospace Revenue (million), by Types 2024 & 2032

- Figure 17: Europe Polyimide Tape for Aerospace Revenue Share (%), by Types 2024 & 2032

- Figure 18: Europe Polyimide Tape for Aerospace Revenue (million), by Country 2024 & 2032

- Figure 19: Europe Polyimide Tape for Aerospace Revenue Share (%), by Country 2024 & 2032

- Figure 20: Middle East & Africa Polyimide Tape for Aerospace Revenue (million), by Application 2024 & 2032

- Figure 21: Middle East & Africa Polyimide Tape for Aerospace Revenue Share (%), by Application 2024 & 2032

- Figure 22: Middle East & Africa Polyimide Tape for Aerospace Revenue (million), by Types 2024 & 2032

- Figure 23: Middle East & Africa Polyimide Tape for Aerospace Revenue Share (%), by Types 2024 & 2032

- Figure 24: Middle East & Africa Polyimide Tape for Aerospace Revenue (million), by Country 2024 & 2032

- Figure 25: Middle East & Africa Polyimide Tape for Aerospace Revenue Share (%), by Country 2024 & 2032

- Figure 26: Asia Pacific Polyimide Tape for Aerospace Revenue (million), by Application 2024 & 2032

- Figure 27: Asia Pacific Polyimide Tape for Aerospace Revenue Share (%), by Application 2024 & 2032

- Figure 28: Asia Pacific Polyimide Tape for Aerospace Revenue (million), by Types 2024 & 2032

- Figure 29: Asia Pacific Polyimide Tape for Aerospace Revenue Share (%), by Types 2024 & 2032

- Figure 30: Asia Pacific Polyimide Tape for Aerospace Revenue (million), by Country 2024 & 2032

- Figure 31: Asia Pacific Polyimide Tape for Aerospace Revenue Share (%), by Country 2024 & 2032

List of Tables

- Table 1: Global Polyimide Tape for Aerospace Revenue million Forecast, by Region 2019 & 2032

- Table 2: Global Polyimide Tape for Aerospace Revenue million Forecast, by Application 2019 & 2032

- Table 3: Global Polyimide Tape for Aerospace Revenue million Forecast, by Types 2019 & 2032

- Table 4: Global Polyimide Tape for Aerospace Revenue million Forecast, by Region 2019 & 2032

- Table 5: Global Polyimide Tape for Aerospace Revenue million Forecast, by Application 2019 & 2032

- Table 6: Global Polyimide Tape for Aerospace Revenue million Forecast, by Types 2019 & 2032

- Table 7: Global Polyimide Tape for Aerospace Revenue million Forecast, by Country 2019 & 2032

- Table 8: United States Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

- Table 9: Canada Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

- Table 10: Mexico Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

- Table 11: Global Polyimide Tape for Aerospace Revenue million Forecast, by Application 2019 & 2032

- Table 12: Global Polyimide Tape for Aerospace Revenue million Forecast, by Types 2019 & 2032

- Table 13: Global Polyimide Tape for Aerospace Revenue million Forecast, by Country 2019 & 2032

- Table 14: Brazil Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

- Table 15: Argentina Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

- Table 16: Rest of South America Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

- Table 17: Global Polyimide Tape for Aerospace Revenue million Forecast, by Application 2019 & 2032

- Table 18: Global Polyimide Tape for Aerospace Revenue million Forecast, by Types 2019 & 2032

- Table 19: Global Polyimide Tape for Aerospace Revenue million Forecast, by Country 2019 & 2032

- Table 20: United Kingdom Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

- Table 21: Germany Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

- Table 22: France Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

- Table 23: Italy Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

- Table 24: Spain Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

- Table 25: Russia Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

- Table 26: Benelux Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

- Table 27: Nordics Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

- Table 28: Rest of Europe Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

- Table 29: Global Polyimide Tape for Aerospace Revenue million Forecast, by Application 2019 & 2032

- Table 30: Global Polyimide Tape for Aerospace Revenue million Forecast, by Types 2019 & 2032

- Table 31: Global Polyimide Tape for Aerospace Revenue million Forecast, by Country 2019 & 2032

- Table 32: Turkey Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

- Table 33: Israel Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

- Table 34: GCC Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

- Table 35: North Africa Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

- Table 36: South Africa Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

- Table 37: Rest of Middle East & Africa Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

- Table 38: Global Polyimide Tape for Aerospace Revenue million Forecast, by Application 2019 & 2032

- Table 39: Global Polyimide Tape for Aerospace Revenue million Forecast, by Types 2019 & 2032

- Table 40: Global Polyimide Tape for Aerospace Revenue million Forecast, by Country 2019 & 2032

- Table 41: China Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

- Table 42: India Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

- Table 43: Japan Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

- Table 44: South Korea Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

- Table 45: ASEAN Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

- Table 46: Oceania Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

- Table 47: Rest of Asia Pacific Polyimide Tape for Aerospace Revenue (million) Forecast, by Application 2019 & 2032

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Polyimide Tape for Aerospace?

The projected CAGR is approximately XX%.

2. Which companies are prominent players in the Polyimide Tape for Aerospace?

Key companies in the market include Dunmore, Saint Gobain, DuPont, Elite Tape, 3M, Nitto, Maxi Adhesive Products, Creative Global Services, Can-Do National Tape, Champion Tape, Xiamen Naikos New Material, Scapa Industrial, M3D.

3. What are the main segments of the Polyimide Tape for Aerospace?

The market segments include Application, Types.

4. Can you provide details about the market size?

The market size is estimated to be USD XXX million as of 2022.

5. What are some drivers contributing to market growth?

N/A

6. What are the notable trends driving market growth?

N/A

7. Are there any restraints impacting market growth?

N/A

8. Can you provide examples of recent developments in the market?

N/A

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4900.00, USD 7350.00, and USD 9800.00 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in million.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Polyimide Tape for Aerospace," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Polyimide Tape for Aerospace report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Polyimide Tape for Aerospace?

To stay informed about further developments, trends, and reports in the Polyimide Tape for Aerospace, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence