Key Insights

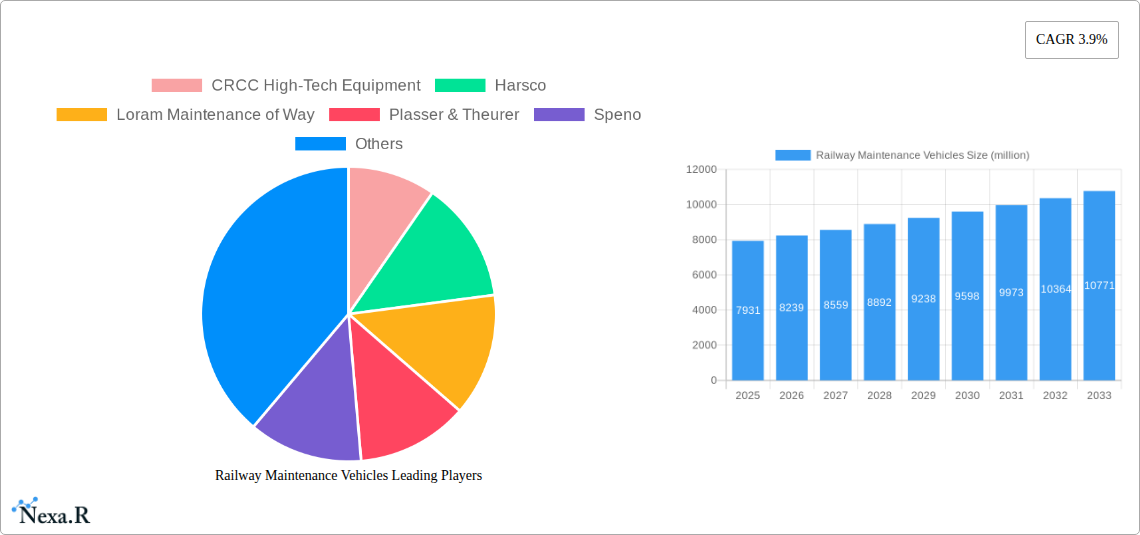

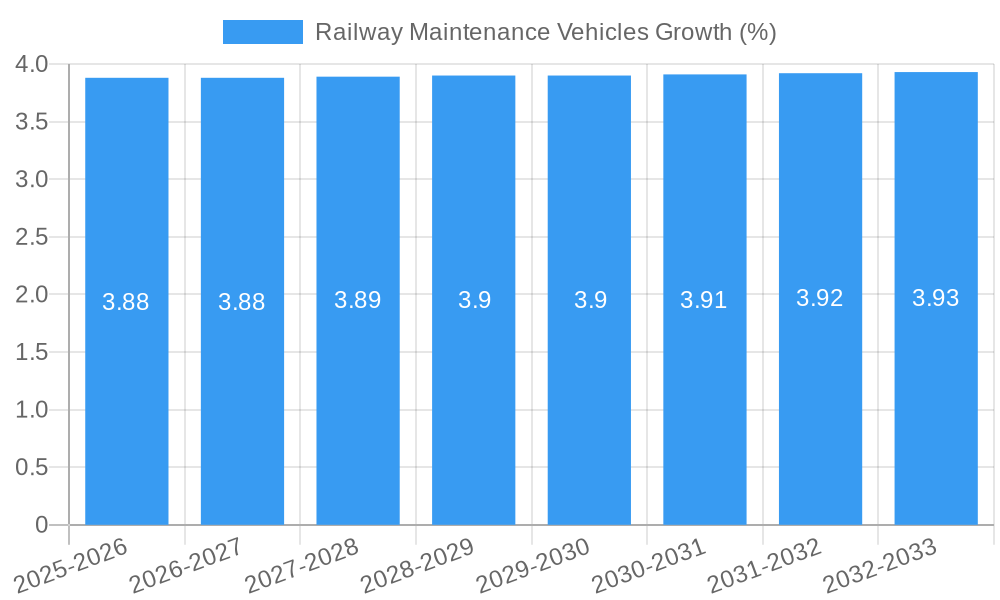

The global railway maintenance vehicles market is poised for significant expansion, projected to reach an estimated USD 7,931 million in 2025, with a robust Compound Annual Growth Rate (CAGR) of 3.9% throughout the forecast period of 2025-2033. This growth is primarily fueled by the escalating need for efficient and cost-effective railway infrastructure upkeep. Aging railway networks across developed regions necessitate regular maintenance and upgrades, driving demand for advanced tamping machines, rail grinding trains, and ballast cleaning machines. Furthermore, emerging economies are heavily investing in new railway lines and modernization projects, creating substantial opportunities for railway maintenance vehicle manufacturers. The increasing focus on improving operational efficiency, reducing downtime, and ensuring passenger safety are key determinants propelling the market forward. Technological advancements, such as the integration of automation and digital solutions into maintenance vehicles, are also expected to play a crucial role in shaping market dynamics, offering enhanced precision and productivity.

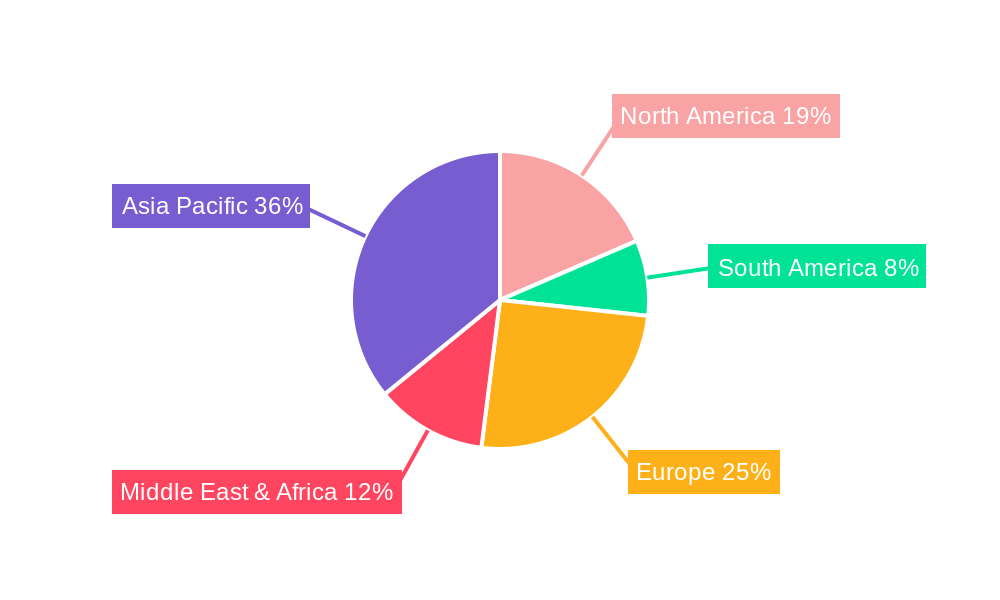

The market's segmentation reveals a dynamic landscape driven by diverse applications and specialized equipment. Ballastless track maintenance is gaining traction due to its longevity and reduced upkeep requirements, while ballast track maintenance continues to be a significant segment, demanding a range of machinery for track bed conditioning. Tamping machines and rail grinding trains represent core segments, vital for maintaining track geometry and rail integrity. Ballast cleaning machines are indispensable for preserving track structure and extending its lifespan. Geographically, Asia Pacific, led by China and India, is anticipated to be a dominant force due to extensive infrastructure development and high-speed rail expansion. North America and Europe will remain significant markets, driven by the refurbishment of existing networks and the adoption of advanced maintenance technologies. Companies like CRCC High-Tech Equipment, Harsco, and Plasser & Theurer are at the forefront, innovating and catering to the evolving demands of this critical industry.

This comprehensive report offers an in-depth analysis of the global Railway Maintenance Vehicles market, meticulously examining its dynamics, growth trends, product landscape, and future outlook. Covering the historical period from 2019 to 2024 and extending to a forecast period of 2025-2033, with a base year of 2025, this report is an indispensable resource for industry stakeholders, investors, and decision-makers seeking to navigate this critical infrastructure sector. We provide precise quantitative data, including market share percentages and projected growth rates, alongside qualitative insights into technological advancements, regulatory shifts, and competitive strategies. The report breaks down the market by key applications, including Ballast Track and Ballastless Track, and by essential vehicle types such as Tamping Machines, Rail Grinding Trains, Stabilizing Machinery, Rail Handling Machinery, Ballast Cleaning Machines, and Others. We also delve into the parent and child market segments to offer a holistic view of market interdependencies and opportunities.

Railway Maintenance Vehicles Market Dynamics & Structure

The global Railway Maintenance Vehicles market is characterized by a moderate concentration, with key players like CRCC High-Tech Equipment, Harsco, Loram Maintenance of Way, Plasser & Theurer, Speno, Nordco, Remputmash Group, CRRC, MATISA France, Teraspyora-Steelwheel, Vortok International, and Beijing Yan Hong Da Railway Equipment holding significant sway. Technological innovation remains a primary driver, fueled by the demand for increased efficiency, enhanced safety, and reduced environmental impact in rail infrastructure upkeep. Regulatory frameworks, particularly those focused on safety standards and environmental compliance, are shaping product development and market access. Competitive product substitutes are limited due to the specialized nature of these vehicles, though advancements in automation and remote monitoring present potential disruptive forces. End-user demographics are primarily government railway authorities and private rail operators, with a growing influence from urban transport agencies. Merger and acquisition (M&A) trends indicate strategic consolidation to expand product portfolios and geographical reach. In the historical period (2019-2024), approximately $3,500 million in M&A deals were observed, indicating active consolidation. The innovation barrier for new entrants is significant due to high capital investment and established technological expertise of incumbent players.

Railway Maintenance Vehicles Growth Trends & Insights

The Railway Maintenance Vehicles market is projected for robust growth, driven by substantial investments in rail infrastructure upgrades and expansion across the globe. The global market size for railway maintenance vehicles was valued at approximately $8,200 million in 2025 and is anticipated to reach $13,500 million by 2033, exhibiting a compound annual growth rate (CAGR) of approximately 6.5% during the forecast period. Adoption rates for advanced and automated maintenance machinery are steadily increasing as railway operators prioritize efficiency and safety. Technological disruptions, such as the integration of AI for predictive maintenance, advanced robotics for track repair, and the development of autonomous maintenance vehicles, are poised to redefine the market landscape. Consumer behavior shifts are evident, with a greater emphasis on lifecycle cost, sustainability, and integrated maintenance solutions rather than standalone machinery. Market penetration is expected to deepen in emerging economies undergoing rapid railway network development. These trends highlight a dynamic market driven by both the necessity of maintaining existing infrastructure and the ambition to build new, advanced railway systems. The increasing focus on high-speed rail networks and the need to maintain them to stringent standards further contribute to the sustained demand for specialized maintenance equipment.

Dominant Regions, Countries, or Segments in Railway Maintenance Vehicles

The Ballast Track application segment is currently the dominant force in the Railway Maintenance Vehicles market, projected to hold a significant market share of approximately 65% by 2025. This dominance is attributed to the extensive global presence of traditional ballast track infrastructure, particularly in established railway networks across North America, Europe, and Asia. Within this segment, Tamping Machines are the leading product type, accounting for an estimated 30% of the total market share in 2025, owing to their crucial role in maintaining track geometry and stability. Key drivers for this dominance include the sheer volume of existing ballast track requiring continuous maintenance, government policies mandating track safety and integrity, and the ongoing need to address wear and tear from high-volume rail traffic.

- North America: This region is a major consumer due to its extensive freight and passenger rail networks. The US alone accounts for a substantial portion of the global demand, driven by an aging infrastructure that requires constant rehabilitation. Regulatory frameworks emphasizing safety and reliability further boost the demand for advanced maintenance vehicles.

- Europe: Characterized by a highly developed and dense rail network, Europe sees consistent demand for both routine and specialized maintenance. Investments in high-speed rail and the modernization of existing lines contribute significantly to market growth. The push for sustainable railway operations also influences the adoption of more energy-efficient and environmentally friendly maintenance vehicles.

- Asia-Pacific: This region is a significant growth engine, propelled by rapid railway expansion, particularly in China and India. The construction of new high-speed rail lines and the modernization of conventional networks are creating unprecedented demand for a wide range of railway maintenance vehicles. Government initiatives to improve connectivity and economic development are key policy drivers.

The Tamping Machine product type, within the Ballast Track application, is a consistent performer, driven by its indispensable function in ensuring track alignment and passenger comfort. Market share for Tamping Machines was valued at around $2,460 million in 2025. The continuous need for trackbed consolidation and alignment adjustments in high-traffic areas ensures sustained demand.

Railway Maintenance Vehicles Product Landscape

The Railway Maintenance Vehicles product landscape is characterized by continuous innovation focused on enhanced efficiency, automation, and environmental sustainability. Modern tamping machines now incorporate advanced sensor technologies for precise track geometry correction, while rail grinding trains utilize sophisticated profiling systems to optimize rail life and reduce noise pollution. Stabilizing machinery is evolving with integrated data analytics for real-time performance monitoring. Rail handling machinery is becoming more versatile and automated, capable of lifting and placing heavier components with greater precision. Ballast cleaning machines are witnessing improvements in their ability to handle a wider range of ballast conditions and minimize environmental disturbance. Companies are differentiating themselves through integrated software solutions for fleet management and predictive maintenance, offering customers comprehensive lifecycle support and optimized operational performance.

Key Drivers, Barriers & Challenges in Railway Maintenance Vehicles

Key Drivers:

- Infrastructure Investment: Significant global investments in railway network expansion, upgrades, and modernization are the primary growth catalyst.

- Safety Regulations: Stringent government regulations mandating high safety standards for rail operations necessitate regular and advanced track maintenance.

- Technological Advancements: Innovations in automation, robotics, and AI are driving demand for more efficient and sophisticated maintenance vehicles.

- Sustainability Initiatives: Growing environmental concerns and the push for greener transportation solutions are encouraging the adoption of energy-efficient maintenance equipment.

Barriers & Challenges:

- High Capital Costs: The substantial initial investment required for purchasing specialized railway maintenance vehicles can be a barrier, particularly for smaller operators.

- Economic Downturns: Global economic uncertainties and recessions can lead to reduced infrastructure spending, impacting demand for new equipment.

- Skilled Workforce Shortage: Operating and maintaining advanced maintenance vehicles requires a skilled workforce, and a shortage of such talent can hinder adoption and utilization.

- Supply Chain Disruptions: Global supply chain vulnerabilities can lead to delays in the production and delivery of critical components and finished vehicles, impacting manufacturers and operators.

Emerging Opportunities in Railway Maintenance Vehicles

Emerging opportunities in the Railway Maintenance Vehicles market are significantly influenced by the growth of high-speed rail networks and the increasing adoption of smart technologies. The development of modular and adaptable maintenance solutions that can serve both ballast and ballastless tracks presents a significant avenue for growth. Furthermore, the demand for specialized vehicles for metro and light rail systems, particularly in rapidly urbanizing regions, is expanding. The integration of IoT sensors for real-time data collection and analysis to enable predictive maintenance offers substantial value-added services for manufacturers. Opportunities also lie in the development of more compact and maneuverable vehicles suitable for confined urban environments and the increasing focus on hybrid or electric-powered maintenance equipment to reduce carbon footprints.

Growth Accelerators in the Railway Maintenance Vehicles Industry

Several key factors are accelerating the growth within the Railway Maintenance Vehicles industry. Technological breakthroughs in autonomous operation and remote diagnostics are enhancing efficiency and reducing operational costs. Strategic partnerships between vehicle manufacturers and railway operators are fostering the development of tailored solutions and improving service delivery. Market expansion strategies, particularly into emerging economies with developing railway infrastructure, are opening up new revenue streams. The increasing demand for integrated maintenance solutions, encompassing not just machinery but also software and services, is a significant growth driver, allowing companies to offer comprehensive packages and capture greater market value.

Key Players Shaping the Railway Maintenance Vehicles Market

- CRCC High-Tech Equipment

- Harsco

- Loram Maintenance of Way

- Plasser & Theurer

- Speno

- Nordco

- Remputmash Group

- CRRC

- MATISA France

- Teraspyora-Steelwheel

- Vortok International

- Beijing Yan Hong Da Railway Equipment

Notable Milestones in Railway Maintenance Vehicles Sector

- 2019: Introduction of AI-powered diagnostic systems for tamping machines by Plasser & Theurer, enhancing predictive maintenance capabilities.

- 2020: Harsco Rail launches a new generation of autonomous ballast cleaning machines designed for improved efficiency and reduced environmental impact.

- 2021: CRRC rolls out a series of advanced high-speed rail maintenance vehicles equipped with real-time monitoring and data analytics for the China Railway network.

- 2022: Loram Maintenance of Way expands its fleet of rail grinding trains with enhanced profiling technology to cater to the growing demand for high-speed line maintenance.

- 2023: Speno introduces an innovative laser-based measurement system for its rail grinding trains, enabling unprecedented precision in rail profile management.

- 2024: MATISA France announces a strategic partnership with a leading European railway operator to develop a fully electric tamping machine prototype.

In-Depth Railway Maintenance Vehicles Market Outlook

The future market outlook for Railway Maintenance Vehicles is exceptionally promising, driven by sustained global investment in rail infrastructure and the relentless pursuit of operational excellence. Growth accelerators such as the widespread adoption of smart technologies, including IoT and AI, will continue to redefine maintenance practices, leading to more predictive and efficient operations. Strategic partnerships and market expansion into developing regions will further fuel demand. The increasing emphasis on sustainable and eco-friendly solutions will also create opportunities for manufacturers to innovate in areas like electric-powered machinery. Overall, the market is poised for continued expansion, presenting significant opportunities for stakeholders who can adapt to technological advancements and evolving customer needs in this vital sector.

Railway Maintenance Vehicles Segmentation

-

1. Application

- 1.1. Ballast Track

- 1.2. Ballastless Track

-

2. Type

- 2.1. Tamping Machine

- 2.2. Rail Grinding Train

- 2.3. Stabilizing Machinery

- 2.4. Rail Handling Machinery

- 2.5. Ballast Cleaning Machine

- 2.6. Others

Railway Maintenance Vehicles Segmentation By Geography

-

1. North America

- 1.1. United States

- 1.2. Canada

- 1.3. Mexico

-

2. South America

- 2.1. Brazil

- 2.2. Argentina

- 2.3. Rest of South America

-

3. Europe

- 3.1. United Kingdom

- 3.2. Germany

- 3.3. France

- 3.4. Italy

- 3.5. Spain

- 3.6. Russia

- 3.7. Benelux

- 3.8. Nordics

- 3.9. Rest of Europe

-

4. Middle East & Africa

- 4.1. Turkey

- 4.2. Israel

- 4.3. GCC

- 4.4. North Africa

- 4.5. South Africa

- 4.6. Rest of Middle East & Africa

-

5. Asia Pacific

- 5.1. China

- 5.2. India

- 5.3. Japan

- 5.4. South Korea

- 5.5. ASEAN

- 5.6. Oceania

- 5.7. Rest of Asia Pacific

Railway Maintenance Vehicles REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of 3.9% from 2019-2033 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.3. Market Restrains

- 3.4. Market Trends

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global Railway Maintenance Vehicles Analysis, Insights and Forecast, 2019-2031

- 5.1. Market Analysis, Insights and Forecast - by Application

- 5.1.1. Ballast Track

- 5.1.2. Ballastless Track

- 5.2. Market Analysis, Insights and Forecast - by Type

- 5.2.1. Tamping Machine

- 5.2.2. Rail Grinding Train

- 5.2.3. Stabilizing Machinery

- 5.2.4. Rail Handling Machinery

- 5.2.5. Ballast Cleaning Machine

- 5.2.6. Others

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. North America

- 5.3.2. South America

- 5.3.3. Europe

- 5.3.4. Middle East & Africa

- 5.3.5. Asia Pacific

- 5.1. Market Analysis, Insights and Forecast - by Application

- 6. North America Railway Maintenance Vehicles Analysis, Insights and Forecast, 2019-2031

- 6.1. Market Analysis, Insights and Forecast - by Application

- 6.1.1. Ballast Track

- 6.1.2. Ballastless Track

- 6.2. Market Analysis, Insights and Forecast - by Type

- 6.2.1. Tamping Machine

- 6.2.2. Rail Grinding Train

- 6.2.3. Stabilizing Machinery

- 6.2.4. Rail Handling Machinery

- 6.2.5. Ballast Cleaning Machine

- 6.2.6. Others

- 6.1. Market Analysis, Insights and Forecast - by Application

- 7. South America Railway Maintenance Vehicles Analysis, Insights and Forecast, 2019-2031

- 7.1. Market Analysis, Insights and Forecast - by Application

- 7.1.1. Ballast Track

- 7.1.2. Ballastless Track

- 7.2. Market Analysis, Insights and Forecast - by Type

- 7.2.1. Tamping Machine

- 7.2.2. Rail Grinding Train

- 7.2.3. Stabilizing Machinery

- 7.2.4. Rail Handling Machinery

- 7.2.5. Ballast Cleaning Machine

- 7.2.6. Others

- 7.1. Market Analysis, Insights and Forecast - by Application

- 8. Europe Railway Maintenance Vehicles Analysis, Insights and Forecast, 2019-2031

- 8.1. Market Analysis, Insights and Forecast - by Application

- 8.1.1. Ballast Track

- 8.1.2. Ballastless Track

- 8.2. Market Analysis, Insights and Forecast - by Type

- 8.2.1. Tamping Machine

- 8.2.2. Rail Grinding Train

- 8.2.3. Stabilizing Machinery

- 8.2.4. Rail Handling Machinery

- 8.2.5. Ballast Cleaning Machine

- 8.2.6. Others

- 8.1. Market Analysis, Insights and Forecast - by Application

- 9. Middle East & Africa Railway Maintenance Vehicles Analysis, Insights and Forecast, 2019-2031

- 9.1. Market Analysis, Insights and Forecast - by Application

- 9.1.1. Ballast Track

- 9.1.2. Ballastless Track

- 9.2. Market Analysis, Insights and Forecast - by Type

- 9.2.1. Tamping Machine

- 9.2.2. Rail Grinding Train

- 9.2.3. Stabilizing Machinery

- 9.2.4. Rail Handling Machinery

- 9.2.5. Ballast Cleaning Machine

- 9.2.6. Others

- 9.1. Market Analysis, Insights and Forecast - by Application

- 10. Asia Pacific Railway Maintenance Vehicles Analysis, Insights and Forecast, 2019-2031

- 10.1. Market Analysis, Insights and Forecast - by Application

- 10.1.1. Ballast Track

- 10.1.2. Ballastless Track

- 10.2. Market Analysis, Insights and Forecast - by Type

- 10.2.1. Tamping Machine

- 10.2.2. Rail Grinding Train

- 10.2.3. Stabilizing Machinery

- 10.2.4. Rail Handling Machinery

- 10.2.5. Ballast Cleaning Machine

- 10.2.6. Others

- 10.1. Market Analysis, Insights and Forecast - by Application

- 11. Competitive Analysis

- 11.1. Global Market Share Analysis 2024

- 11.2. Company Profiles

- 11.2.1 CRCC High-Tech Equipment

- 11.2.1.1. Overview

- 11.2.1.2. Products

- 11.2.1.3. SWOT Analysis

- 11.2.1.4. Recent Developments

- 11.2.1.5. Financials (Based on Availability)

- 11.2.2 Harsco

- 11.2.2.1. Overview

- 11.2.2.2. Products

- 11.2.2.3. SWOT Analysis

- 11.2.2.4. Recent Developments

- 11.2.2.5. Financials (Based on Availability)

- 11.2.3 Loram Maintenance of Way

- 11.2.3.1. Overview

- 11.2.3.2. Products

- 11.2.3.3. SWOT Analysis

- 11.2.3.4. Recent Developments

- 11.2.3.5. Financials (Based on Availability)

- 11.2.4 Plasser & Theurer

- 11.2.4.1. Overview

- 11.2.4.2. Products

- 11.2.4.3. SWOT Analysis

- 11.2.4.4. Recent Developments

- 11.2.4.5. Financials (Based on Availability)

- 11.2.5 Speno

- 11.2.5.1. Overview

- 11.2.5.2. Products

- 11.2.5.3. SWOT Analysis

- 11.2.5.4. Recent Developments

- 11.2.5.5. Financials (Based on Availability)

- 11.2.6 Nordco

- 11.2.6.1. Overview

- 11.2.6.2. Products

- 11.2.6.3. SWOT Analysis

- 11.2.6.4. Recent Developments

- 11.2.6.5. Financials (Based on Availability)

- 11.2.7 Remputmash Group

- 11.2.7.1. Overview

- 11.2.7.2. Products

- 11.2.7.3. SWOT Analysis

- 11.2.7.4. Recent Developments

- 11.2.7.5. Financials (Based on Availability)

- 11.2.8 CRRC

- 11.2.8.1. Overview

- 11.2.8.2. Products

- 11.2.8.3. SWOT Analysis

- 11.2.8.4. Recent Developments

- 11.2.8.5. Financials (Based on Availability)

- 11.2.9 MATISA France

- 11.2.9.1. Overview

- 11.2.9.2. Products

- 11.2.9.3. SWOT Analysis

- 11.2.9.4. Recent Developments

- 11.2.9.5. Financials (Based on Availability)

- 11.2.10 Teraspyora-Steelwheel

- 11.2.10.1. Overview

- 11.2.10.2. Products

- 11.2.10.3. SWOT Analysis

- 11.2.10.4. Recent Developments

- 11.2.10.5. Financials (Based on Availability)

- 11.2.11 Vortok International

- 11.2.11.1. Overview

- 11.2.11.2. Products

- 11.2.11.3. SWOT Analysis

- 11.2.11.4. Recent Developments

- 11.2.11.5. Financials (Based on Availability)

- 11.2.12 Beijing Yan Hong Da Railway Equipment

- 11.2.12.1. Overview

- 11.2.12.2. Products

- 11.2.12.3. SWOT Analysis

- 11.2.12.4. Recent Developments

- 11.2.12.5. Financials (Based on Availability)

- 11.2.1 CRCC High-Tech Equipment

List of Figures

- Figure 1: Global Railway Maintenance Vehicles Revenue Breakdown (million, %) by Region 2024 & 2032

- Figure 2: North America Railway Maintenance Vehicles Revenue (million), by Application 2024 & 2032

- Figure 3: North America Railway Maintenance Vehicles Revenue Share (%), by Application 2024 & 2032

- Figure 4: North America Railway Maintenance Vehicles Revenue (million), by Type 2024 & 2032

- Figure 5: North America Railway Maintenance Vehicles Revenue Share (%), by Type 2024 & 2032

- Figure 6: North America Railway Maintenance Vehicles Revenue (million), by Country 2024 & 2032

- Figure 7: North America Railway Maintenance Vehicles Revenue Share (%), by Country 2024 & 2032

- Figure 8: South America Railway Maintenance Vehicles Revenue (million), by Application 2024 & 2032

- Figure 9: South America Railway Maintenance Vehicles Revenue Share (%), by Application 2024 & 2032

- Figure 10: South America Railway Maintenance Vehicles Revenue (million), by Type 2024 & 2032

- Figure 11: South America Railway Maintenance Vehicles Revenue Share (%), by Type 2024 & 2032

- Figure 12: South America Railway Maintenance Vehicles Revenue (million), by Country 2024 & 2032

- Figure 13: South America Railway Maintenance Vehicles Revenue Share (%), by Country 2024 & 2032

- Figure 14: Europe Railway Maintenance Vehicles Revenue (million), by Application 2024 & 2032

- Figure 15: Europe Railway Maintenance Vehicles Revenue Share (%), by Application 2024 & 2032

- Figure 16: Europe Railway Maintenance Vehicles Revenue (million), by Type 2024 & 2032

- Figure 17: Europe Railway Maintenance Vehicles Revenue Share (%), by Type 2024 & 2032

- Figure 18: Europe Railway Maintenance Vehicles Revenue (million), by Country 2024 & 2032

- Figure 19: Europe Railway Maintenance Vehicles Revenue Share (%), by Country 2024 & 2032

- Figure 20: Middle East & Africa Railway Maintenance Vehicles Revenue (million), by Application 2024 & 2032

- Figure 21: Middle East & Africa Railway Maintenance Vehicles Revenue Share (%), by Application 2024 & 2032

- Figure 22: Middle East & Africa Railway Maintenance Vehicles Revenue (million), by Type 2024 & 2032

- Figure 23: Middle East & Africa Railway Maintenance Vehicles Revenue Share (%), by Type 2024 & 2032

- Figure 24: Middle East & Africa Railway Maintenance Vehicles Revenue (million), by Country 2024 & 2032

- Figure 25: Middle East & Africa Railway Maintenance Vehicles Revenue Share (%), by Country 2024 & 2032

- Figure 26: Asia Pacific Railway Maintenance Vehicles Revenue (million), by Application 2024 & 2032

- Figure 27: Asia Pacific Railway Maintenance Vehicles Revenue Share (%), by Application 2024 & 2032

- Figure 28: Asia Pacific Railway Maintenance Vehicles Revenue (million), by Type 2024 & 2032

- Figure 29: Asia Pacific Railway Maintenance Vehicles Revenue Share (%), by Type 2024 & 2032

- Figure 30: Asia Pacific Railway Maintenance Vehicles Revenue (million), by Country 2024 & 2032

- Figure 31: Asia Pacific Railway Maintenance Vehicles Revenue Share (%), by Country 2024 & 2032

List of Tables

- Table 1: Global Railway Maintenance Vehicles Revenue million Forecast, by Region 2019 & 2032

- Table 2: Global Railway Maintenance Vehicles Revenue million Forecast, by Application 2019 & 2032

- Table 3: Global Railway Maintenance Vehicles Revenue million Forecast, by Type 2019 & 2032

- Table 4: Global Railway Maintenance Vehicles Revenue million Forecast, by Region 2019 & 2032

- Table 5: Global Railway Maintenance Vehicles Revenue million Forecast, by Application 2019 & 2032

- Table 6: Global Railway Maintenance Vehicles Revenue million Forecast, by Type 2019 & 2032

- Table 7: Global Railway Maintenance Vehicles Revenue million Forecast, by Country 2019 & 2032

- Table 8: United States Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

- Table 9: Canada Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

- Table 10: Mexico Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

- Table 11: Global Railway Maintenance Vehicles Revenue million Forecast, by Application 2019 & 2032

- Table 12: Global Railway Maintenance Vehicles Revenue million Forecast, by Type 2019 & 2032

- Table 13: Global Railway Maintenance Vehicles Revenue million Forecast, by Country 2019 & 2032

- Table 14: Brazil Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

- Table 15: Argentina Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

- Table 16: Rest of South America Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

- Table 17: Global Railway Maintenance Vehicles Revenue million Forecast, by Application 2019 & 2032

- Table 18: Global Railway Maintenance Vehicles Revenue million Forecast, by Type 2019 & 2032

- Table 19: Global Railway Maintenance Vehicles Revenue million Forecast, by Country 2019 & 2032

- Table 20: United Kingdom Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

- Table 21: Germany Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

- Table 22: France Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

- Table 23: Italy Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

- Table 24: Spain Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

- Table 25: Russia Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

- Table 26: Benelux Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

- Table 27: Nordics Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

- Table 28: Rest of Europe Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

- Table 29: Global Railway Maintenance Vehicles Revenue million Forecast, by Application 2019 & 2032

- Table 30: Global Railway Maintenance Vehicles Revenue million Forecast, by Type 2019 & 2032

- Table 31: Global Railway Maintenance Vehicles Revenue million Forecast, by Country 2019 & 2032

- Table 32: Turkey Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

- Table 33: Israel Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

- Table 34: GCC Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

- Table 35: North Africa Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

- Table 36: South Africa Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

- Table 37: Rest of Middle East & Africa Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

- Table 38: Global Railway Maintenance Vehicles Revenue million Forecast, by Application 2019 & 2032

- Table 39: Global Railway Maintenance Vehicles Revenue million Forecast, by Type 2019 & 2032

- Table 40: Global Railway Maintenance Vehicles Revenue million Forecast, by Country 2019 & 2032

- Table 41: China Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

- Table 42: India Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

- Table 43: Japan Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

- Table 44: South Korea Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

- Table 45: ASEAN Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

- Table 46: Oceania Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

- Table 47: Rest of Asia Pacific Railway Maintenance Vehicles Revenue (million) Forecast, by Application 2019 & 2032

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Railway Maintenance Vehicles?

The projected CAGR is approximately 3.9%.

2. Which companies are prominent players in the Railway Maintenance Vehicles?

Key companies in the market include CRCC High-Tech Equipment, Harsco, Loram Maintenance of Way, Plasser & Theurer, Speno, Nordco, Remputmash Group, CRRC, MATISA France, Teraspyora-Steelwheel, Vortok International, Beijing Yan Hong Da Railway Equipment.

3. What are the main segments of the Railway Maintenance Vehicles?

The market segments include Application, Type.

4. Can you provide details about the market size?

The market size is estimated to be USD 7931 million as of 2022.

5. What are some drivers contributing to market growth?

N/A

6. What are the notable trends driving market growth?

N/A

7. Are there any restraints impacting market growth?

N/A

8. Can you provide examples of recent developments in the market?

N/A

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 2900.00, USD 4350.00, and USD 5800.00 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in million.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Railway Maintenance Vehicles," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Railway Maintenance Vehicles report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Railway Maintenance Vehicles?

To stay informed about further developments, trends, and reports in the Railway Maintenance Vehicles, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence