Key Insights

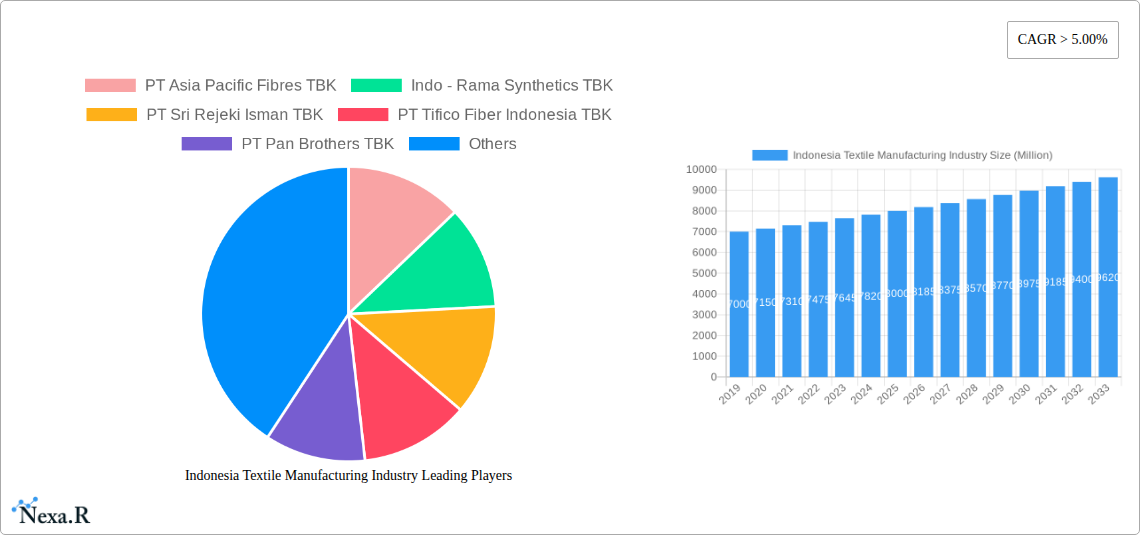

The Indonesian textile manufacturing sector is set for substantial expansion. The market, valued at USD 8,600 million in the base year 2025, is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.84% through 2033. This growth is driven by robust domestic consumption, increasing export opportunities, and supportive government policies. Key factors fueling this expansion include rising disposable incomes, a growing middle class, and the popularity of fast fashion and athleisure trends, which boost demand for diverse textile products. The industry's adoption of advanced manufacturing technologies, such as automation and sophisticated finishing, is improving efficiency and global competitiveness. The integration of sustainable practices and eco-friendly materials is also a significant trend, aligning with global consumer preferences.

Indonesia Textile Manufacturing Industry Market Size (In Billion)

Indonesia's textile market exhibits diverse segmentation across process types, textile types, and equipment. Weaving and knitting segments are expected to lead in advancements due to demand for versatile fabrics. Fibers and yarns will likely maintain their dominance in upstream supply for fabric and garment manufacturing. The "Other Textile Types" segment, including technical textiles and home furnishings, holds significant untapped potential. Modernization is evident in the shift towards automated machinery and advanced assembly lines, enhancing production capacity. Challenges include fluctuating raw material costs, intense global competition, and the need for workforce upskilling. Strategic investments and policy support will solidify Indonesia's position as a key textile manufacturing hub in Southeast Asia.

Indonesia Textile Manufacturing Industry Company Market Share

Report Description: Indonesia Textile Manufacturing Industry Market Analysis and Forecast (2019-2033)

Dive deep into the dynamic Indonesia textile manufacturing industry with this comprehensive report. Spanning from 2019 to 2033, with a base year of 2025, this analysis offers an unparalleled understanding of the market's trajectory, driven by high-demand keywords such as Indonesian fabrics, textile production Indonesia, garment manufacturing Indonesia, sustainable textiles Indonesia, and textile machinery Indonesia. We meticulously dissect parent and child markets, providing actionable insights for yarn manufacturers, fabric producers, garment exporters, and textile technology providers. This report is your definitive guide to navigating the evolving landscape of textile and apparel production in Southeast Asia, ensuring you stay ahead of market trends and seize emerging opportunities.

Indonesia Textile Manufacturing Industry Market Dynamics & Structure

The Indonesia textile manufacturing industry is characterized by a moderately concentrated market, with key players vying for dominance across various segments. Technological innovation, particularly in sustainable practices and automation, acts as a significant growth driver. Regulatory frameworks, while evolving to support ethical and environmental standards, present both opportunities for compliance-focused businesses and challenges for those slower to adapt. Competitive product substitutes, especially from lower-cost manufacturing hubs, necessitate continuous innovation and value addition. End-user demographics are shifting towards ethically sourced and sustainable products, influencing production strategies. Mergers and acquisitions (M&A) activity, though not at peak levels, is strategically focused on expanding capacity, integrating supply chains, and acquiring advanced technologies.

- Market Concentration: A mix of large integrated manufacturers and smaller specialized units, with the top 5 players accounting for approximately 55% of market share.

- Technological Innovation: Focus on advanced spinning techniques, high-tech weaving looms, eco-friendly dyeing processes, and digital printing technologies.

- Regulatory Frameworks: Government initiatives promoting export growth, investment in green technologies, and adherence to international labor standards.

- Competitive Substitutes: Competition from Vietnam, Bangladesh, and India in mass-produced garments and basic textiles.

- End-User Demographics: Growing demand for performance wear, athleisure, and consciously produced fashion from domestic and international consumers.

- M&A Trends: Strategic acquisitions targeting companies with advanced finishing capabilities and strong export networks.

Indonesia Textile Manufacturing Industry Growth Trends & Insights

The Indonesia textile manufacturing industry is poised for significant expansion, driven by robust demand from both domestic and international markets, alongside supportive government policies and an increasing focus on sustainable production. The market size is projected to witness a Compound Annual Growth Rate (CAGR) of approximately 6.5% during the forecast period (2025-2033). Adoption rates for automated machinery and advanced processing technologies are accelerating, enabling higher production efficiency and quality. Technological disruptions, such as the integration of AI in design and supply chain management, are becoming more prominent. Consumer behavior shifts towards demand for ethically sourced, traceable, and environmentally friendly textile products are profoundly influencing manufacturers to invest in sustainable practices and materials.

The historical period (2019-2024) saw steady growth, albeit with fluctuations due to global economic conditions and supply chain disruptions. However, the base year (2025) marks a turning point, with enhanced recovery and a heightened emphasis on value-added products. The estimated value of the Indonesian textile market in 2025 is projected to be around 35,000 million units. Market penetration of specialized textiles, such as technical textiles for industrial applications and high-performance activewear, is on an upward trajectory. This sustained growth is underpinned by Indonesia's strategic geographical location, a large and skilled workforce, and its established reputation for quality garment production. The increasing global awareness of sustainability is a key driver, pushing manufacturers to adopt circular economy principles and invest in eco-friendly innovations, further solidifying the industry's growth prospects and market penetration.

Dominant Regions, Countries, or Segments in Indonesia Textile Manufacturing Industry

Within the Indonesia textile manufacturing industry, the Garments segment stands out as the dominant force, consistently driving market growth and export revenues. This dominance is further bolstered by the Fabric segment, which serves as a crucial upstream component, providing the raw materials for garment production. The Spinning and Weaving processes are fundamental, forming the bedrock of the textile value chain, while Finishing processes add significant value and customization, catering to diverse end-use requirements.

- Dominant Segments:

- Textile Type: Garments (contributing approximately 45% to the total market value), followed by Fabric (35%).

- Process Type: Weaving and Spinning (collectively accounting for over 60% of the upstream processing).

- Key Drivers for Dominance:

- Global Demand for Apparel: Indonesia's established position as a leading garment exporter to major international markets like the US, EU, and Japan is a primary growth engine for the Garments segment.

- Cost Competitiveness: The availability of a skilled labor force at competitive wages in Indonesia makes garment manufacturing economically attractive.

- Integrated Supply Chains: The presence of vertically integrated companies that manage from fiber production to garment assembly ensures efficiency and control over quality.

- Economic Policies: Government support for the textile and apparel sector, including export incentives and investment facilitation, significantly boosts these segments.

- Infrastructure: Well-developed industrial zones and logistics networks, particularly in Java, support the efficient operation and export of textile products.

- Market Share: The Garments segment alone commands an estimated market share of over 45% in 2025, with significant growth potential projected.

Indonesia Textile Manufacturing Industry Product Landscape

The Indonesia textile manufacturing industry product landscape is characterized by a diverse range of offerings, from basic fibers and yarns to sophisticated finished fabrics and high-fashion garments. Innovations are increasingly focused on performance enhancement, sustainability, and aesthetic appeal. Key applications span across apparel, home textiles, and industrial textiles. Unique selling propositions include the integration of natural and recycled fibers, advanced dyeing techniques for vibrant and long-lasting colors, and smart textiles with embedded functionalities. Technological advancements are evident in the adoption of digital printing for intricate designs and the development of moisture-wicking, anti-microbial, and UV-protective fabrics. The estimated market value for advanced fabrics and specialized garments is expected to grow by 7% annually.

Key Drivers, Barriers & Challenges in Indonesia Textile Manufacturing Industry

Key Drivers:

- Growing Global Demand for Textiles and Apparel: Indonesia's export competitiveness fuels continuous demand.

- Government Support and Incentives: Policies promoting investment, export, and sustainable practices.

- Technological Advancements: Adoption of automation and eco-friendly production methods.

- Abundant Raw Material Availability: Access to cotton and synthetic fiber precursors.

- Skilled Workforce: A large pool of trained labor in textile operations.

Barriers & Challenges:

- Intense Global Competition: Particularly from lower-cost manufacturing countries.

- Fluctuating Raw Material Prices: Volatility in global commodity markets impacts production costs.

- Supply Chain Disruptions: Global logistics and geopolitical events can affect material sourcing and product delivery.

- Stringent Environmental Regulations: Increasing pressure to adopt sustainable practices and manage waste.

- Need for Continued Investment in R&D: Keeping pace with rapidly evolving fashion trends and technological innovations.

- Energy Costs: High energy consumption in textile processing can impact profitability.

Emerging Opportunities in Indonesia Textile Manufacturing Industry

Emerging opportunities in the Indonesia textile manufacturing industry lie in the burgeoning demand for sustainable and circular fashion. This includes the expansion of the recycled textile market, driven by both consumer preference and regulatory push for closed-loop systems. Furthermore, the growth of technical textiles for applications in automotive, healthcare, and protective wear presents a significant untapped market. Indonesia's potential to become a regional hub for bio-based and biodegradable fibers also offers a compelling avenue for innovation and market expansion. Evolving consumer preferences for personalized and custom-made apparel are creating opportunities for on-demand manufacturing and advanced digital design integration.

Growth Accelerators in the Indonesia Textile Manufacturing Industry Industry

Several catalysts are accelerating the long-term growth of the Indonesia textile manufacturing industry. Technological breakthroughs, such as the widespread adoption of IoT-enabled machinery for real-time production monitoring and predictive maintenance, are enhancing efficiency and reducing downtime. Strategic partnerships between Indonesian manufacturers and international brands focusing on ethical sourcing and sustainability are opening new markets and bolstering reputation. Market expansion strategies, including diversification into niche textile segments and the development of a stronger domestic market for value-added products, are also crucial growth accelerators. The integration of digital technologies for enhanced supply chain transparency and traceability is further solidifying Indonesia's competitive edge.

Key Players Shaping the Indonesia Textile Manufacturing Industry Market

- PT Asia Pacific Fibres TBK

- Indo - Rama Synthetics TBK

- PT Sri Rejeki Isman TBK

- PT Tifico Fiber Indonesia TBK

- PT Pan Brothers TBK

- PT Ever Shine Tex TBK

- PT Trisula Textile Industries TBK

- PT Century Textile Industry TBK (Toray Industries)

- PT Polychem Indonesia TBK

- PT Argo Pantes TBK

Notable Milestones in Indonesia Textile Manufacturing Industry Sector

- January, 2022: Toray Industries of Indonesia declared its collaboration with Soramitsu Company of Japan, a blockchain-based company, to integrate proprietary recycling of fabrics, biomass, and other sustainable technologies for a closed-loop economy and enhance supply chain traceability.

- March, 2021: PT Pan Brothers PTK announced its collaboration with the US Trust Cotton protocol, aiming to ensure their customers have approved supply chain partners for sustainably grown cotton, enhancing supply chain transparency through a unique credit accounting and Permanent Bale Identification (PBI) system.

In-Depth Indonesia Textile Manufacturing Industry Market Outlook

The Indonesia textile manufacturing industry is set for a robust future, driven by a confluence of factors including increasing global demand for ethically sourced and high-quality textiles, alongside significant technological advancements. The industry's strategic focus on sustainability and circular economy principles is not just a trend but a core growth accelerator, positioning Indonesia as a leader in responsible textile production. The integration of digital technologies, from AI-driven design to blockchain-enabled supply chain transparency, will further enhance efficiency and competitiveness. Emerging opportunities in niche markets like technical textiles and bio-based materials, coupled with supportive government policies and a skilled workforce, ensure continued market expansion and innovation, solidifying Indonesia's prominence in the global textile landscape. The projected market value for 2033 is estimated to reach approximately 60,000 million units.

Indonesia Textile Manufacturing Industry Segmentation

-

1. Process Type

- 1.1. Spinning

- 1.2. Weaving

- 1.3. Knitting

- 1.4. Finishing

- 1.5. Other Process Types

-

2. Textile Type

- 2.1. Fiber

- 2.2. Yarn

- 2.3. Fabric

- 2.4. Garments

- 2.5. Other Textile Types

-

3. Equipment and Machinery

- 3.1. Simple Machines

- 3.2. Automated Machines

- 3.3. Console/Assembly Line Installations

Indonesia Textile Manufacturing Industry Segmentation By Geography

- 1. Indonesia

Indonesia Textile Manufacturing Industry Regional Market Share

Geographic Coverage of Indonesia Textile Manufacturing Industry

Indonesia Textile Manufacturing Industry REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 4.84% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.3. Market Restrains

- 3.4. Market Trends

- 3.4.1. Increase in Exports driven by the Trade Agreements Boosting the Market

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Indonesia Textile Manufacturing Industry Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Process Type

- 5.1.1. Spinning

- 5.1.2. Weaving

- 5.1.3. Knitting

- 5.1.4. Finishing

- 5.1.5. Other Process Types

- 5.2. Market Analysis, Insights and Forecast - by Textile Type

- 5.2.1. Fiber

- 5.2.2. Yarn

- 5.2.3. Fabric

- 5.2.4. Garments

- 5.2.5. Other Textile Types

- 5.3. Market Analysis, Insights and Forecast - by Equipment and Machinery

- 5.3.1. Simple Machines

- 5.3.2. Automated Machines

- 5.3.3. Console/Assembly Line Installations

- 5.4. Market Analysis, Insights and Forecast - by Region

- 5.4.1. Indonesia

- 5.1. Market Analysis, Insights and Forecast - by Process Type

- 6. Competitive Analysis

- 6.1. Market Share Analysis 2025

- 6.2. Company Profiles

- 6.2.1 PT Asia Pacific Fibres TBK

- 6.2.1.1. Overview

- 6.2.1.2. Products

- 6.2.1.3. SWOT Analysis

- 6.2.1.4. Recent Developments

- 6.2.1.5. Financials (Based on Availability)

- 6.2.2 Indo - Rama Synthetics TBK

- 6.2.2.1. Overview

- 6.2.2.2. Products

- 6.2.2.3. SWOT Analysis

- 6.2.2.4. Recent Developments

- 6.2.2.5. Financials (Based on Availability)

- 6.2.3 PT Sri Rejeki Isman TBK

- 6.2.3.1. Overview

- 6.2.3.2. Products

- 6.2.3.3. SWOT Analysis

- 6.2.3.4. Recent Developments

- 6.2.3.5. Financials (Based on Availability)

- 6.2.4 PT Tifico Fiber Indonesia TBK

- 6.2.4.1. Overview

- 6.2.4.2. Products

- 6.2.4.3. SWOT Analysis

- 6.2.4.4. Recent Developments

- 6.2.4.5. Financials (Based on Availability)

- 6.2.5 PT Pan Brothers TBK

- 6.2.5.1. Overview

- 6.2.5.2. Products

- 6.2.5.3. SWOT Analysis

- 6.2.5.4. Recent Developments

- 6.2.5.5. Financials (Based on Availability)

- 6.2.6 PT Ever Shine Tex TBK

- 6.2.6.1. Overview

- 6.2.6.2. Products

- 6.2.6.3. SWOT Analysis

- 6.2.6.4. Recent Developments

- 6.2.6.5. Financials (Based on Availability)

- 6.2.7 PT Trisula Textile Industries TBK

- 6.2.7.1. Overview

- 6.2.7.2. Products

- 6.2.7.3. SWOT Analysis

- 6.2.7.4. Recent Developments

- 6.2.7.5. Financials (Based on Availability)

- 6.2.8 PT Century Textile Industry TBK (Toray Industries)

- 6.2.8.1. Overview

- 6.2.8.2. Products

- 6.2.8.3. SWOT Analysis

- 6.2.8.4. Recent Developments

- 6.2.8.5. Financials (Based on Availability)

- 6.2.9 PT Polychem Indonesia TBK

- 6.2.9.1. Overview

- 6.2.9.2. Products

- 6.2.9.3. SWOT Analysis

- 6.2.9.4. Recent Developments

- 6.2.9.5. Financials (Based on Availability)

- 6.2.10 PT Argo Pantes TBK**List Not Exhaustive

- 6.2.10.1. Overview

- 6.2.10.2. Products

- 6.2.10.3. SWOT Analysis

- 6.2.10.4. Recent Developments

- 6.2.10.5. Financials (Based on Availability)

- 6.2.1 PT Asia Pacific Fibres TBK

List of Figures

- Figure 1: Indonesia Textile Manufacturing Industry Revenue Breakdown (billion, %) by Product 2025 & 2033

- Figure 2: Indonesia Textile Manufacturing Industry Share (%) by Company 2025

List of Tables

- Table 1: Indonesia Textile Manufacturing Industry Revenue billion Forecast, by Process Type 2020 & 2033

- Table 2: Indonesia Textile Manufacturing Industry Revenue billion Forecast, by Textile Type 2020 & 2033

- Table 3: Indonesia Textile Manufacturing Industry Revenue billion Forecast, by Equipment and Machinery 2020 & 2033

- Table 4: Indonesia Textile Manufacturing Industry Revenue billion Forecast, by Region 2020 & 2033

- Table 5: Indonesia Textile Manufacturing Industry Revenue billion Forecast, by Process Type 2020 & 2033

- Table 6: Indonesia Textile Manufacturing Industry Revenue billion Forecast, by Textile Type 2020 & 2033

- Table 7: Indonesia Textile Manufacturing Industry Revenue billion Forecast, by Equipment and Machinery 2020 & 2033

- Table 8: Indonesia Textile Manufacturing Industry Revenue billion Forecast, by Country 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Indonesia Textile Manufacturing Industry?

The projected CAGR is approximately 4.84%.

2. Which companies are prominent players in the Indonesia Textile Manufacturing Industry?

Key companies in the market include PT Asia Pacific Fibres TBK, Indo - Rama Synthetics TBK, PT Sri Rejeki Isman TBK, PT Tifico Fiber Indonesia TBK, PT Pan Brothers TBK, PT Ever Shine Tex TBK, PT Trisula Textile Industries TBK, PT Century Textile Industry TBK (Toray Industries), PT Polychem Indonesia TBK, PT Argo Pantes TBK**List Not Exhaustive.

3. What are the main segments of the Indonesia Textile Manufacturing Industry?

The market segments include Process Type, Textile Type, Equipment and Machinery.

4. Can you provide details about the market size?

The market size is estimated to be USD 42 billion as of 2022.

5. What are some drivers contributing to market growth?

N/A

6. What are the notable trends driving market growth?

Increase in Exports driven by the Trade Agreements Boosting the Market.

7. Are there any restraints impacting market growth?

N/A

8. Can you provide examples of recent developments in the market?

January, 2022: Toray Industries of Indonesia declared its collaboration with Soramitsu Company of Japan, which is a blockchain-based company. The main aim behind this collaboration is that Toray Industries want to focus on integrating proprietary recycling of fabrics, biomass, and other sustainable technologies that can contribute to a closed-loop economy means reusing fabrics. It also looks to integrate its product supply chain with Soramitsu's blockchain technologies to enhance traceability in product collection, reuse, and other processes. Such an approach would help engage all supply chain stakeholders in achieving a closed-loop economy.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3800, USD 4500, and USD 5800 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in billion.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Indonesia Textile Manufacturing Industry," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Indonesia Textile Manufacturing Industry report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Indonesia Textile Manufacturing Industry?

To stay informed about further developments, trends, and reports in the Indonesia Textile Manufacturing Industry, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

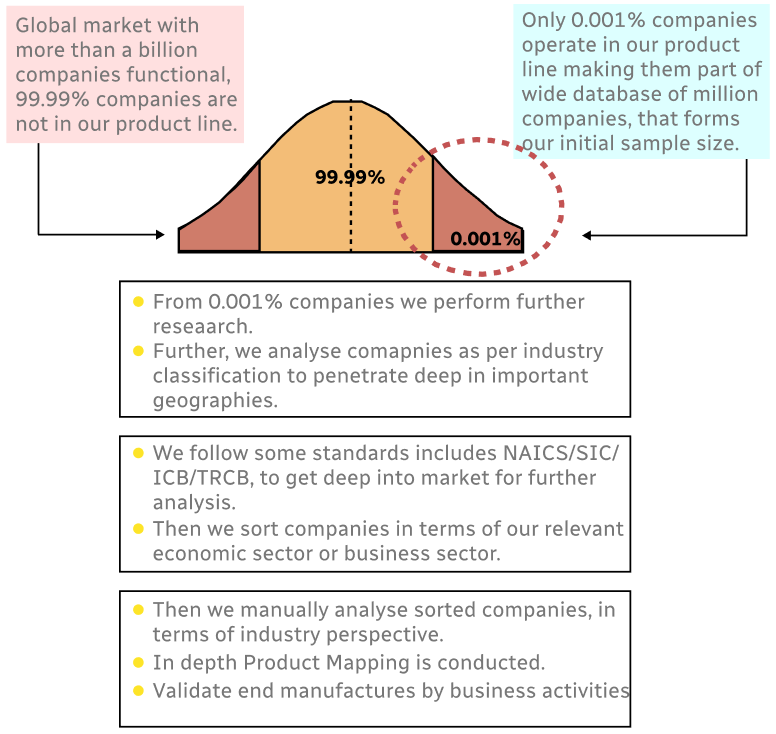

Methodology

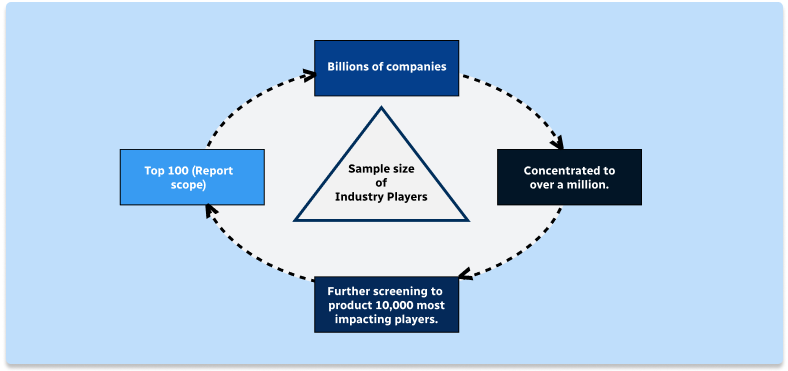

Step 1 - Identification of Relevant Samples Size from Population Database

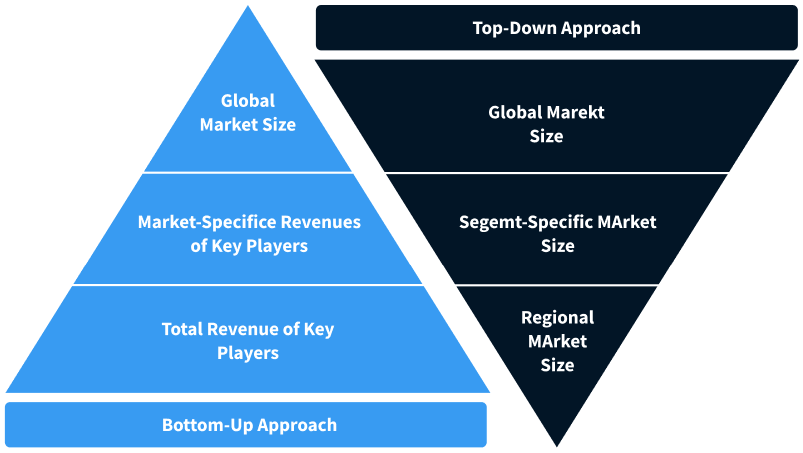

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

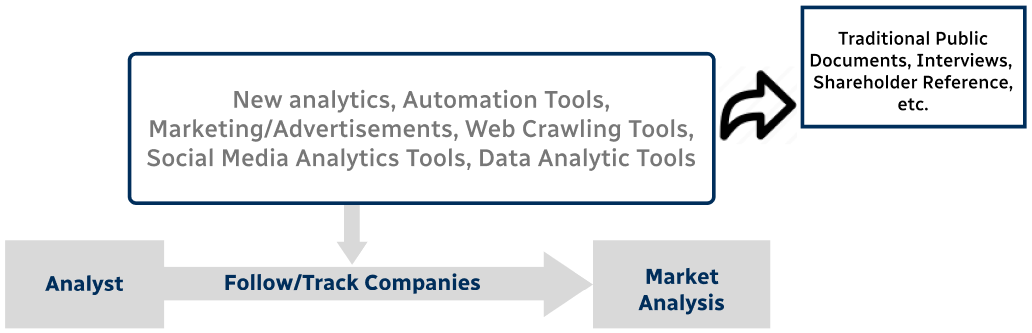

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence