Key Insights

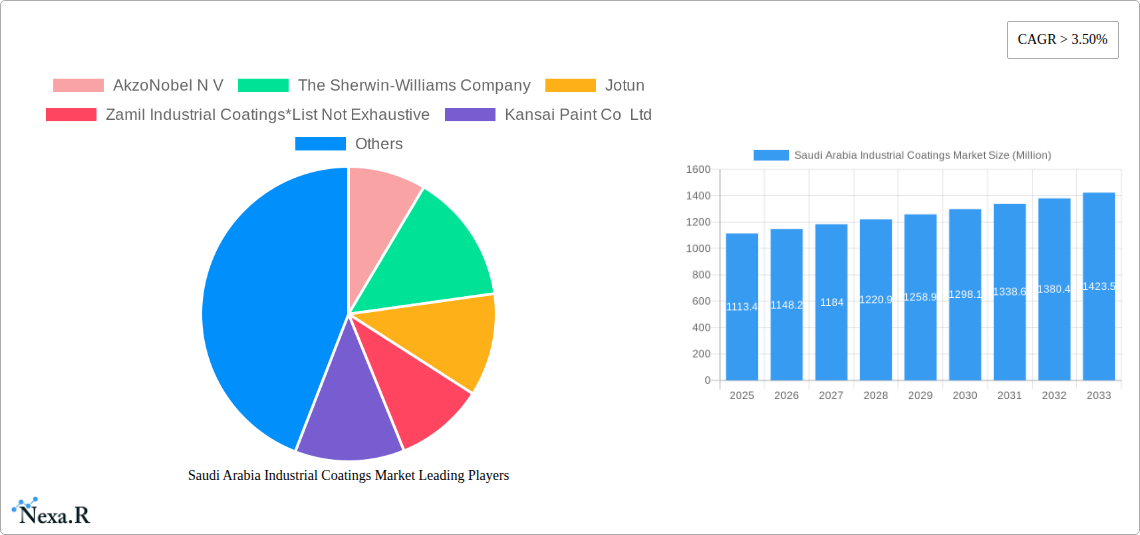

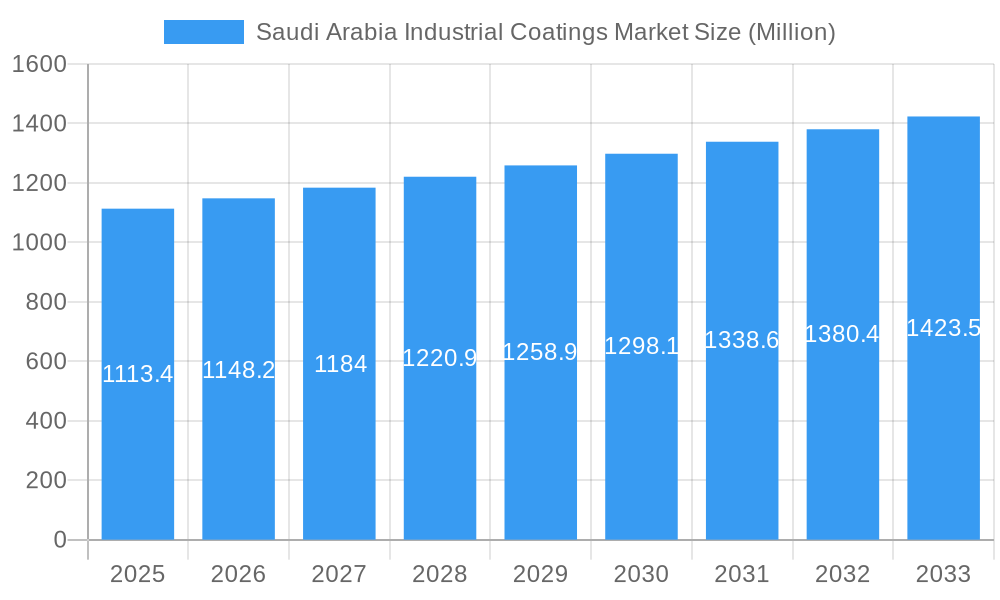

The Saudi Arabia Industrial Coatings Market is poised for robust growth, driven by significant investments in infrastructure, oil and gas, and manufacturing sectors. With an estimated market size of $1113.4 million in 2025, the market is projected to expand at a Compound Annual Growth Rate (CAGR) of 3.12% through 2033. This expansion is fueled by the increasing demand for protective coatings that offer enhanced durability, corrosion resistance, and aesthetic appeal across a wide array of applications, including general industrial use, oil and gas exploration and production, mining operations, power generation facilities, and vital infrastructure projects. The Kingdom's Vision 2030 initiative, with its focus on economic diversification and large-scale development projects, acts as a primary catalyst, stimulating the need for advanced coating solutions that can withstand harsh environmental conditions and extend the lifespan of assets. Furthermore, the growing adoption of innovative technologies such as water-borne and powder coatings, driven by environmental regulations and a push towards sustainability, is expected to shape market dynamics significantly.

Saudi Arabia Industrial Coatings Market Market Size (In Billion)

The market segmentation reveals a strong demand across various resin types, with Epoxy, Polyester, and Vinyl Ester resins dominating due to their superior performance characteristics. Technology-wise, while solvent-borne coatings retain a considerable share, there is a discernible shift towards more eco-friendly alternatives like water-borne and powder coatings, reflecting a global trend towards sustainable manufacturing practices. The demand for specialized protective coatings is particularly high within the oil and gas sector, where extreme conditions necessitate advanced protection against corrosion and chemical degradation. Key players like AkzoNobel N.V., The Sherwin-Williams Company, Jotun, and PPG Industries Inc. are actively participating in this market, introducing innovative products and expanding their regional presence to cater to the escalating demand. The ongoing industrialization and infrastructure development initiatives across Saudi Arabia will continue to be the backbone of this market's sustained upward trajectory.

Saudi Arabia Industrial Coatings Market Company Market Share

Here's a compelling and SEO-optimized report description for the Saudi Arabia Industrial Coatings Market:

Saudi Arabia Industrial Coatings Market: Comprehensive Analysis, Growth Trends, and Future Outlook (2019–2033)

This in-depth report provides a strategic overview of the Saudi Arabia Industrial Coatings Market, a rapidly evolving sector driven by robust industrial expansion and government initiatives. Covering the period from 2019 to 2033, with a base year of 2025 and a forecast period of 2025–2033, this analysis offers critical insights into market dynamics, growth trends, competitive landscape, and emerging opportunities. We delve into key segments including Resin Type (Epoxy, Polyester, Vinyl Ester, Polyurethane, Other Resin Types), Technology (Water-borne, Solvent-borne, Radiation-cured Coatings, Powder Coatings), and Product Type (General Industrial, Protective – including Oil and Gas, Mining, Power, Infrastructure, Others). With comprehensive data and expert analysis, this report is essential for stakeholders seeking to understand and capitalize on the immense potential within the Saudi Arabian industrial coatings sector.

Saudi Arabia Industrial Coatings Market Market Dynamics & Structure

The Saudi Arabia industrial coatings market is characterized by a moderately concentrated structure, with a few dominant players controlling a significant market share. Technological innovation is a primary driver, fueled by the increasing demand for high-performance, sustainable, and application-specific coatings. Regulatory frameworks, though evolving, are increasingly emphasizing environmental compliance and safety standards, influencing product development and adoption. Competitive product substitutes, while present, are largely addressed by the continuous innovation in coating formulations and application technologies. End-user demographics showcase a growing sophistication in requirements, with a focus on durability, corrosion resistance, and aesthetic appeal across various industrial applications. Mergers and acquisitions (M&A) activity, while not excessively high, plays a role in market consolidation and expansion, enabling key players to enhance their product portfolios and geographical reach.

- Market Concentration: Dominated by leading international and regional players, but with room for specialized niche providers.

- Technological Innovation: Driven by R&D in sustainable formulations, advanced protective properties, and efficient application methods.

- Regulatory Frameworks: Increasing focus on VOC reduction, durability standards, and environmental impact assessments.

- Competitive Product Substitutes: Primarily addressed through performance differentiation and tailored solutions.

- End-User Demographics: Demand for enhanced performance, longevity, and specific functionalities across diverse industries.

- M&A Trends: Strategic acquisitions aimed at market expansion and technological integration.

Saudi Arabia Industrial Coatings Market Growth Trends & Insights

The Saudi Arabia Industrial Coatings Market is poised for significant expansion, driven by a confluence of economic diversification strategies and substantial infrastructure development projects. The Kingdom's Vision 2030 plan acts as a powerful catalyst, stimulating investment across key sectors such as oil and gas, petrochemicals, construction, and manufacturing, all of which are major consumers of industrial coatings. This ongoing industrialization translates into a consistently growing demand for protective, decorative, and functional coatings designed to withstand the harsh environmental conditions prevalent in the region. The adoption of advanced coating technologies, including water-borne and powder coatings, is on an upward trajectory, reflecting a growing emphasis on environmental sustainability and reduced volatile organic compound (VOC) emissions. Consumer behavior is shifting towards high-performance coatings that offer superior durability, corrosion resistance, and extended service life, thereby reducing maintenance costs for end-users. The market size is projected to experience a healthy Compound Annual Growth Rate (CAGR) of approximately 6.5% during the forecast period, indicating substantial market penetration for innovative solutions. This growth is further underscored by the increasing penetration of specialized coatings for sectors like renewable energy infrastructure and smart city development. The estimated market size in 2025 is expected to reach approximately $1,500 million, growing to over $2,400 million by 2033. Technological disruptions, such as advancements in nanotechnology for enhanced coating properties and smart coatings with self-healing capabilities, are also expected to play a crucial role in shaping market evolution and consumer preferences.

Dominant Regions, Countries, or Segments in Saudi Arabia Industrial Coatings Market

The Saudi Arabia Industrial Coatings Market is predominantly driven by the Protective segment, particularly within the Oil and Gas and Infrastructure sub-segments, due to the Kingdom's extensive energy sector and ambitious Giga-projects. The Oil and Gas industry, a cornerstone of the Saudi economy, consistently demands high-performance protective coatings to safeguard pipelines, storage tanks, offshore platforms, and refining facilities from extreme corrosion and environmental degradation. This necessitates the use of specialized resin types such as Epoxy and Vinyl Ester, known for their exceptional chemical resistance and durability. The Infrastructure segment is experiencing unprecedented growth, fueled by Vision 2030 initiatives, including the development of new cities, transportation networks (e.g., high-speed rail, airports), and industrial complexes. These projects require vast quantities of coatings for bridges, buildings, steel structures, and concrete surfaces, with a growing preference for durable and aesthetically pleasing finishes.

Within Resin Type, Epoxy coatings are a dominant force, owing to their superior adhesion, chemical resistance, and mechanical strength, making them ideal for heavy-duty protective applications. Polyurethane coatings are also gaining traction for their excellent UV resistance and flexibility, particularly in architectural and automotive applications. Regarding Technology, while Solvent-borne coatings have historically held a significant share due to their performance and cost-effectiveness, Water-borne coatings are witnessing rapid adoption. This shift is largely driven by stringent environmental regulations mandating reduced VOC emissions and a growing industry commitment to sustainability. Powder Coatings are also emerging as a significant technology, offering an environmentally friendly, durable, and efficient coating solution for various metal substrates. The General Industrial segment also contributes significantly, encompassing coatings for machinery, appliances, and metal fabrication, where performance and cost-efficiency are key considerations. Economic policies supporting industrial diversification and local manufacturing, coupled with massive investments in infrastructure and energy projects, are the primary drivers of dominance for these segments. For instance, the sheer scale of projects like NEOM and the Red Sea Project directly translates into substantial market share for protective and infrastructure coatings, estimated to account for over 60% of the total market value in 2025.

Saudi Arabia Industrial Coatings Market Product Landscape

The product landscape of the Saudi Arabia Industrial Coatings Market is characterized by a continuous stream of innovations aimed at enhancing performance, sustainability, and application efficiency. Key product developments include advanced epoxy formulations offering superior corrosion resistance in aggressive environments, and fast-curing polyurethane coatings designed for high-throughput industrial applications. The increasing demand for eco-friendly solutions is driving the proliferation of low-VOC and water-borne coatings, without compromising on durability or protective properties. Furthermore, specialized coatings for extreme temperature resistance and UV protection are gaining prominence, catering to the region's climatic conditions. Radiation-cured coatings are also finding niche applications for their rapid curing times and high-performance attributes in specific manufacturing processes.

Key Drivers, Barriers & Challenges in Saudi Arabia Industrial Coatings Market

Key Drivers:

- Vision 2030 Initiatives: Massive government investment in infrastructure, tourism, and industrial diversification projects is a primary growth catalyst.

- Oil and Gas Sector Expansion: Continued exploration, production, and refining activities necessitate robust protective coatings.

- Construction Boom: Development of new cities, commercial buildings, and residential complexes drives demand for architectural and protective coatings.

- Sustainability Focus: Growing adoption of environmentally friendly, low-VOC, and water-borne coating technologies.

- Technological Advancements: Innovations in high-performance, durable, and functional coatings.

Barriers & Challenges:

- Supply Chain Volatility: Potential disruptions in raw material sourcing and logistics can impact production and costs.

- Skilled Labor Shortage: A need for trained applicators and technicians to ensure optimal coating performance.

- Intense Competition: Presence of global and regional players can lead to price pressures.

- Economic Fluctuations: Dependency on global oil prices can influence overall industrial investment.

- Regulatory Compliance: Adapting to evolving environmental and safety standards can require significant investment.

Emerging Opportunities in Saudi Arabia Industrial Coatings Market

Emerging opportunities in the Saudi Arabia Industrial Coatings Market lie in the burgeoning renewable energy sector, particularly solar power projects, which require specialized coatings for panels and infrastructure. The growing focus on digitalization and smart cities presents a demand for coatings with integrated functionalities, such as self-cleaning or anti-microbial properties. Furthermore, the increasing emphasis on localized manufacturing and the "Made in Saudi" initiative creates opportunities for domestic players to expand their production capabilities and cater to the growing demand for industrial coatings. Untapped markets in specialized industrial applications, such as marine coatings for port expansions and coatings for advanced manufacturing, also represent significant growth potential.

Growth Accelerators in the Saudi Arabia Industrial Coatings Market Industry

Growth in the Saudi Arabia Industrial Coatings Market is being significantly accelerated by several key factors. The ongoing massive government spending on Giga-projects under Vision 2030, such as NEOM, the Red Sea Project, and Qiddiya, is a primary catalyst, driving demand for a wide array of industrial and protective coatings. Technological advancements in coating formulations, leading to enhanced durability, corrosion resistance, and environmental compliance, are further propelling adoption. Strategic partnerships and joint ventures between international and local coating manufacturers are fostering knowledge transfer and expanding market reach. The increasing adoption of sustainable and eco-friendly coating solutions, including water-borne and powder coatings, aligns with global environmental trends and government mandates, acting as a significant growth accelerator.

Key Players Shaping the Saudi Arabia Industrial Coatings Market Market

- AkzoNobel N V

- The Sherwin-Williams Company

- Jotun

- Zamil Industrial Coatings

- Kansai Paint Co Ltd

- National Paints Factory Co Ltd

- PPG Industries Inc

- Axalta Coating Systems

- Sak Coat

- Protech Powder Coatings Inc

- United Coatings Industries

- Al-Jazeera Paints

Notable Milestones in Saudi Arabia Industrial Coatings Market Sector

- 2019: Launch of Vision 2030 initiatives, signaling a new era of industrial and infrastructure development.

- 2020: Increased focus on local content and manufacturing capabilities in the coatings sector.

- 2021: Introduction of stricter environmental regulations for VOC emissions in industrial coatings.

- 2022: Significant investments in new coating manufacturing facilities by major players to meet growing demand.

- 2023: Growing adoption of water-borne and powder coating technologies for sustainability initiatives.

- 2024: Continued expansion of infrastructure projects, including transportation networks and smart city developments, boosting demand for protective coatings.

- 2025 (Estimated): Projected significant market value increase driven by ongoing mega-projects and industrial expansion.

- 2026-2033 (Forecast): Sustained growth anticipated due to the long-term nature of Vision 2030 projects and ongoing industrial diversification.

In-Depth Saudi Arabia Industrial Coatings Market Market Outlook

The future outlook for the Saudi Arabia Industrial Coatings Market is exceptionally robust, driven by the sustained momentum of Vision 2030 and the proactive diversification of the Saudi economy. Growth accelerators such as substantial infrastructure investments, particularly in emerging Giga-projects and renewable energy installations, will continue to fuel demand for high-performance protective and specialty coatings. Technological innovation remains a critical factor, with an increasing emphasis on sustainable formulations, smart coatings, and advanced application techniques that promise enhanced efficiency and environmental benefits. Strategic collaborations and localized manufacturing efforts are expected to further solidify market growth, fostering a competitive yet collaborative ecosystem. The market is poised for continuous expansion, offering significant opportunities for stakeholders adept at navigating the evolving demands for durability, environmental responsibility, and cutting-edge solutions.

Saudi Arabia Industrial Coatings Market Segmentation

-

1. Resin Type

- 1.1. Epoxy

- 1.2. Polyester

- 1.3. Vinyl Ester

- 1.4. Polyurethane

- 1.5. Other Resin Types

-

2. Technology

- 2.1. Water-borne

- 2.2. Solvent-borne

- 2.3. Radiation-cured Coatings

- 2.4. Powder Coatings

-

3. Product Type

- 3.1. General Industrial

-

3.2. Protective

- 3.2.1. Oil and Gas

- 3.2.2. Mining

- 3.2.3. Power

- 3.2.4. Infrastructure

- 3.2.5. Others

Saudi Arabia Industrial Coatings Market Segmentation By Geography

- 1. Saudi Arabia

Saudi Arabia Industrial Coatings Market Regional Market Share

Geographic Coverage of Saudi Arabia Industrial Coatings Market

Saudi Arabia Industrial Coatings Market REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 3.12% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. ; Increasing Private Investment Participation; Growing Oil and Gas Sector

- 3.3. Market Restrains

- 3.3.1. ; Impact of COVID-19 Pandemic on Global Economy; Other Restraints

- 3.4. Market Trends

- 3.4.1. Growing Oil and Gas Sector to Increase the Demand for Protective Coatings

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Saudi Arabia Industrial Coatings Market Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Resin Type

- 5.1.1. Epoxy

- 5.1.2. Polyester

- 5.1.3. Vinyl Ester

- 5.1.4. Polyurethane

- 5.1.5. Other Resin Types

- 5.2. Market Analysis, Insights and Forecast - by Technology

- 5.2.1. Water-borne

- 5.2.2. Solvent-borne

- 5.2.3. Radiation-cured Coatings

- 5.2.4. Powder Coatings

- 5.3. Market Analysis, Insights and Forecast - by Product Type

- 5.3.1. General Industrial

- 5.3.2. Protective

- 5.3.2.1. Oil and Gas

- 5.3.2.2. Mining

- 5.3.2.3. Power

- 5.3.2.4. Infrastructure

- 5.3.2.5. Others

- 5.4. Market Analysis, Insights and Forecast - by Region

- 5.4.1. Saudi Arabia

- 5.1. Market Analysis, Insights and Forecast - by Resin Type

- 6. Competitive Analysis

- 6.1. Market Share Analysis 2025

- 6.2. Company Profiles

- 6.2.1 AkzoNobel N V

- 6.2.1.1. Overview

- 6.2.1.2. Products

- 6.2.1.3. SWOT Analysis

- 6.2.1.4. Recent Developments

- 6.2.1.5. Financials (Based on Availability)

- 6.2.2 The Sherwin-Williams Company

- 6.2.2.1. Overview

- 6.2.2.2. Products

- 6.2.2.3. SWOT Analysis

- 6.2.2.4. Recent Developments

- 6.2.2.5. Financials (Based on Availability)

- 6.2.3 Jotun

- 6.2.3.1. Overview

- 6.2.3.2. Products

- 6.2.3.3. SWOT Analysis

- 6.2.3.4. Recent Developments

- 6.2.3.5. Financials (Based on Availability)

- 6.2.4 Zamil Industrial Coatings*List Not Exhaustive

- 6.2.4.1. Overview

- 6.2.4.2. Products

- 6.2.4.3. SWOT Analysis

- 6.2.4.4. Recent Developments

- 6.2.4.5. Financials (Based on Availability)

- 6.2.5 Kansai Paint Co Ltd

- 6.2.5.1. Overview

- 6.2.5.2. Products

- 6.2.5.3. SWOT Analysis

- 6.2.5.4. Recent Developments

- 6.2.5.5. Financials (Based on Availability)

- 6.2.6 National Paints Factory Co Ltd

- 6.2.6.1. Overview

- 6.2.6.2. Products

- 6.2.6.3. SWOT Analysis

- 6.2.6.4. Recent Developments

- 6.2.6.5. Financials (Based on Availability)

- 6.2.7 PPG Industries Inc

- 6.2.7.1. Overview

- 6.2.7.2. Products

- 6.2.7.3. SWOT Analysis

- 6.2.7.4. Recent Developments

- 6.2.7.5. Financials (Based on Availability)

- 6.2.8 Axalta Coating Systems

- 6.2.8.1. Overview

- 6.2.8.2. Products

- 6.2.8.3. SWOT Analysis

- 6.2.8.4. Recent Developments

- 6.2.8.5. Financials (Based on Availability)

- 6.2.9 Sak Coat

- 6.2.9.1. Overview

- 6.2.9.2. Products

- 6.2.9.3. SWOT Analysis

- 6.2.9.4. Recent Developments

- 6.2.9.5. Financials (Based on Availability)

- 6.2.10 Protech Powder Coatings Inc

- 6.2.10.1. Overview

- 6.2.10.2. Products

- 6.2.10.3. SWOT Analysis

- 6.2.10.4. Recent Developments

- 6.2.10.5. Financials (Based on Availability)

- 6.2.11 United Coatings Industries

- 6.2.11.1. Overview

- 6.2.11.2. Products

- 6.2.11.3. SWOT Analysis

- 6.2.11.4. Recent Developments

- 6.2.11.5. Financials (Based on Availability)

- 6.2.12 Al-Jazeera Paints

- 6.2.12.1. Overview

- 6.2.12.2. Products

- 6.2.12.3. SWOT Analysis

- 6.2.12.4. Recent Developments

- 6.2.12.5. Financials (Based on Availability)

- 6.2.1 AkzoNobel N V

List of Figures

- Figure 1: Saudi Arabia Industrial Coatings Market Revenue Breakdown (undefined, %) by Product 2025 & 2033

- Figure 2: Saudi Arabia Industrial Coatings Market Share (%) by Company 2025

List of Tables

- Table 1: Saudi Arabia Industrial Coatings Market Revenue undefined Forecast, by Resin Type 2020 & 2033

- Table 2: Saudi Arabia Industrial Coatings Market Volume liter Forecast, by Resin Type 2020 & 2033

- Table 3: Saudi Arabia Industrial Coatings Market Revenue undefined Forecast, by Technology 2020 & 2033

- Table 4: Saudi Arabia Industrial Coatings Market Volume liter Forecast, by Technology 2020 & 2033

- Table 5: Saudi Arabia Industrial Coatings Market Revenue undefined Forecast, by Product Type 2020 & 2033

- Table 6: Saudi Arabia Industrial Coatings Market Volume liter Forecast, by Product Type 2020 & 2033

- Table 7: Saudi Arabia Industrial Coatings Market Revenue undefined Forecast, by Region 2020 & 2033

- Table 8: Saudi Arabia Industrial Coatings Market Volume liter Forecast, by Region 2020 & 2033

- Table 9: Saudi Arabia Industrial Coatings Market Revenue undefined Forecast, by Resin Type 2020 & 2033

- Table 10: Saudi Arabia Industrial Coatings Market Volume liter Forecast, by Resin Type 2020 & 2033

- Table 11: Saudi Arabia Industrial Coatings Market Revenue undefined Forecast, by Technology 2020 & 2033

- Table 12: Saudi Arabia Industrial Coatings Market Volume liter Forecast, by Technology 2020 & 2033

- Table 13: Saudi Arabia Industrial Coatings Market Revenue undefined Forecast, by Product Type 2020 & 2033

- Table 14: Saudi Arabia Industrial Coatings Market Volume liter Forecast, by Product Type 2020 & 2033

- Table 15: Saudi Arabia Industrial Coatings Market Revenue undefined Forecast, by Country 2020 & 2033

- Table 16: Saudi Arabia Industrial Coatings Market Volume liter Forecast, by Country 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Saudi Arabia Industrial Coatings Market?

The projected CAGR is approximately 3.12%.

2. Which companies are prominent players in the Saudi Arabia Industrial Coatings Market?

Key companies in the market include AkzoNobel N V, The Sherwin-Williams Company, Jotun, Zamil Industrial Coatings*List Not Exhaustive, Kansai Paint Co Ltd, National Paints Factory Co Ltd, PPG Industries Inc, Axalta Coating Systems, Sak Coat, Protech Powder Coatings Inc, United Coatings Industries, Al-Jazeera Paints.

3. What are the main segments of the Saudi Arabia Industrial Coatings Market?

The market segments include Resin Type, Technology, Product Type.

4. Can you provide details about the market size?

The market size is estimated to be USD XXX N/A as of 2022.

5. What are some drivers contributing to market growth?

; Increasing Private Investment Participation; Growing Oil and Gas Sector.

6. What are the notable trends driving market growth?

Growing Oil and Gas Sector to Increase the Demand for Protective Coatings.

7. Are there any restraints impacting market growth?

; Impact of COVID-19 Pandemic on Global Economy; Other Restraints.

8. Can you provide examples of recent developments in the market?

N/A

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3800, USD 4500, and USD 5800 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in N/A and volume, measured in liter .

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Saudi Arabia Industrial Coatings Market," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Saudi Arabia Industrial Coatings Market report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Saudi Arabia Industrial Coatings Market?

To stay informed about further developments, trends, and reports in the Saudi Arabia Industrial Coatings Market, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

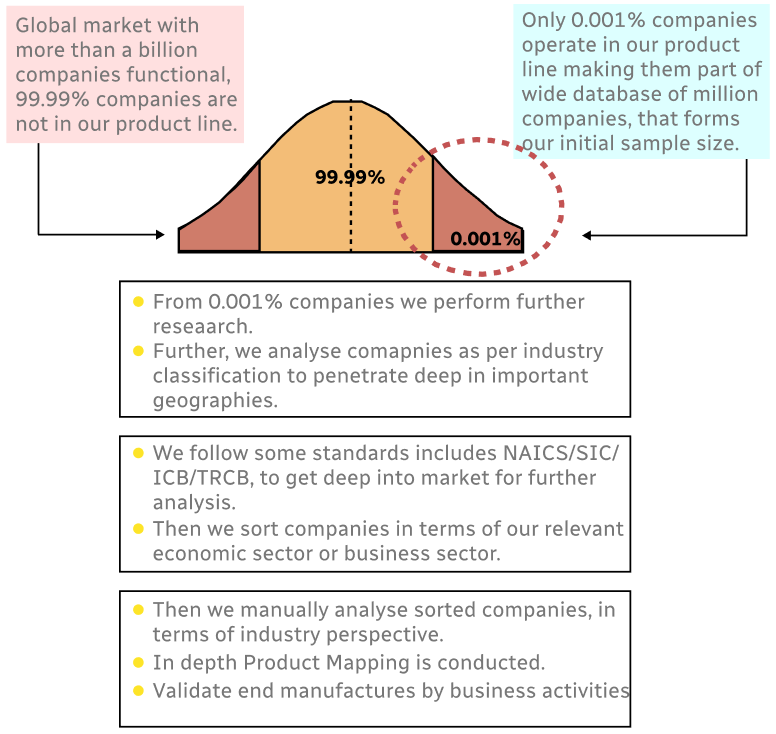

Step 1 - Identification of Relevant Samples Size from Population Database

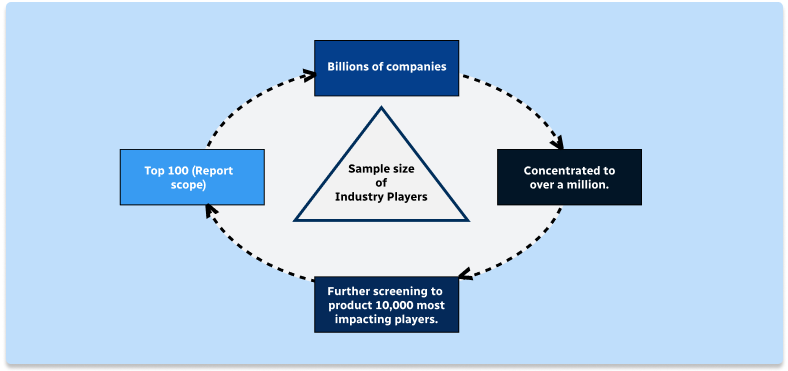

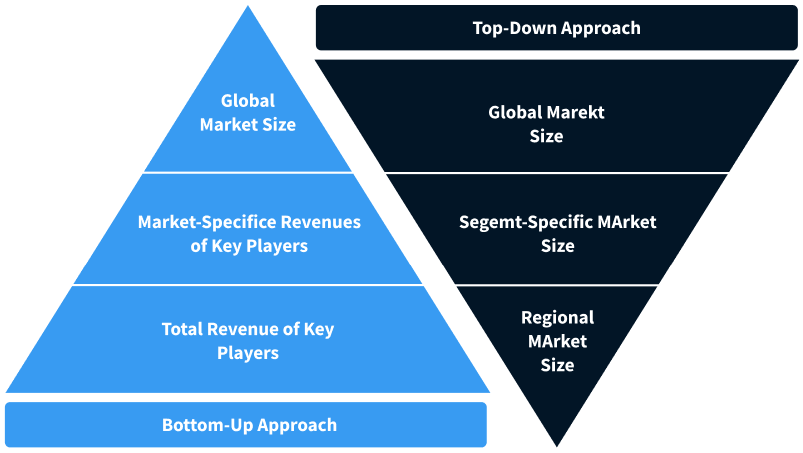

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

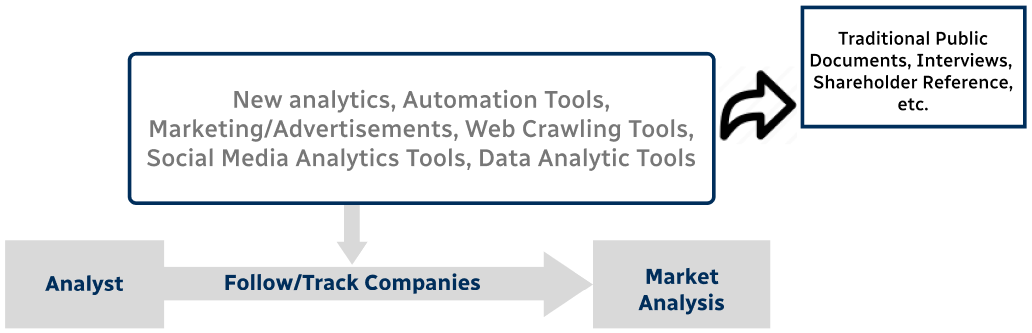

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence