Key Insights

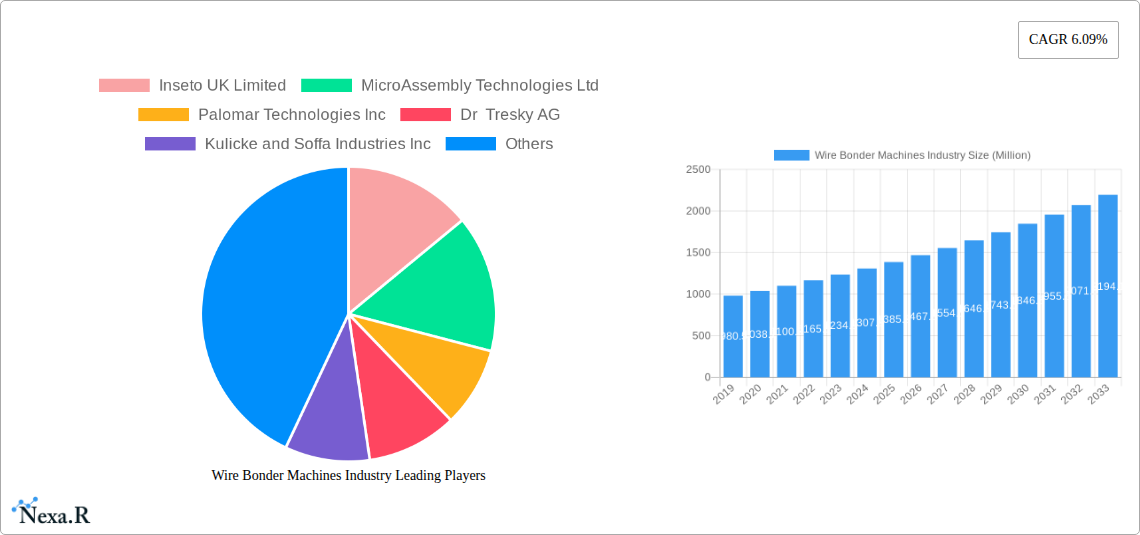

The global wire bonder machines market is poised for significant expansion, projected to reach a substantial market size of $1.45 billion by 2025, with a robust Compound Annual Growth Rate (CAGR) of 6.09% anticipated through 2033. This impressive growth trajectory is primarily propelled by the escalating demand for advanced semiconductor devices across a multitude of industries. Key drivers include the burgeoning consumer electronics sector, the rapid proliferation of the Internet of Things (IoT), and the increasing complexity of memory and logic chips, all of which necessitate sophisticated wire bonding processes. Furthermore, advancements in bonding techniques, such as the adoption of hybrid bonding for higher density interconnects and the continuous refinement of epoxy and eutectic bonding for specialized applications, are fueling market innovation and adoption. The burgeoning adoption of wire bonder machines in applications like CMOS image sensors for mobile devices and automotive systems, as well as in the production of high-brightness LEDs and advanced RF & MEMS components, underscores the technology's critical role in modern manufacturing.

Wire Bonder Machines Industry Market Size (In Million)

Despite the overwhelmingly positive outlook, the market faces certain restraints that warrant attention. High capital expenditure for sophisticated wire bonder equipment can pose a barrier to entry for smaller manufacturers. Additionally, the intricate nature of advanced bonding techniques, such as those required for optoelectronics and photonics, demands specialized expertise and skilled labor, potentially leading to supply chain challenges. However, the industry is actively addressing these through technological advancements aimed at improving automation, reducing operational costs, and developing more user-friendly interfaces. The market is segmented by type, with Die Bonder and Flip Chip Bonder machines leading in adoption. Bonding techniques like Epoxy, Eutectic, and Soft Solder remain crucial, while Hybrid Bonding is emerging as a key growth area. Geographically, Asia is expected to dominate, driven by its position as a global manufacturing hub for electronics.

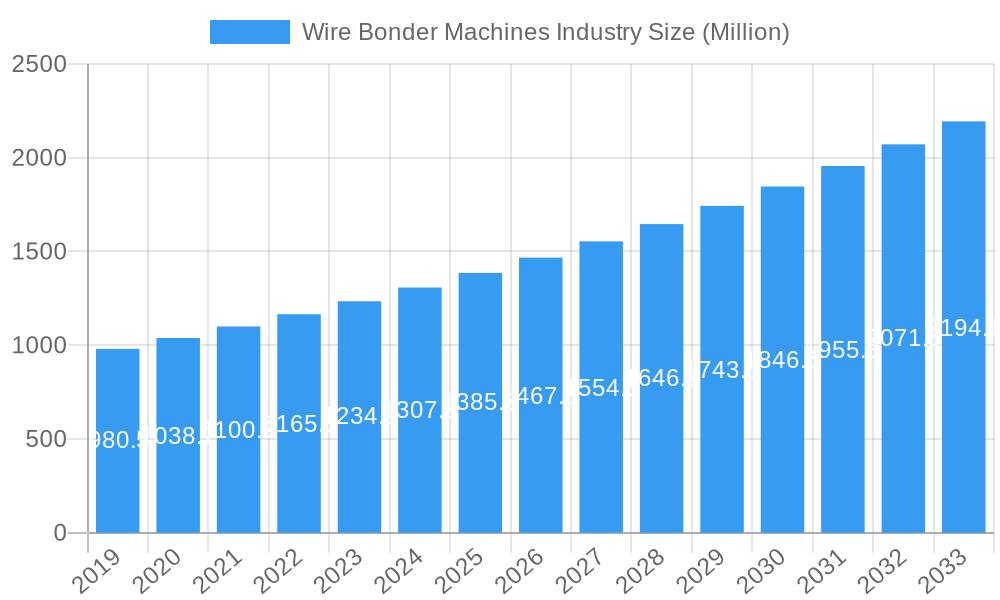

Wire Bonder Machines Industry Company Market Share

This in-depth market report provides a granular analysis of the global Wire Bonder Machines Industry, offering critical insights into its dynamics, growth trajectories, and future outlook. Spanning a comprehensive study period of 2019–2033, with a base year of 2025, this report delves into the intricate workings of this vital sector within the semiconductor packaging ecosystem. We explore both the parent market of advanced semiconductor assembly equipment and its crucial child markets, such as specialized die bonding and flip-chip bonding solutions. This report is essential for manufacturers, equipment suppliers, investors, and industry strategists seeking to navigate the evolving landscape of semiconductor packaging, microelectronics assembly, and advanced electronics manufacturing.

Wire Bonder Machines Industry Market Dynamics & Structure

The Wire Bonder Machines Industry is characterized by a moderate level of market concentration, with a few key players holding significant market share. Technological innovation is the primary driver, fueled by the relentless demand for smaller, faster, and more powerful electronic devices. Advancements in areas like hybrid bonding and ultra-fine pitch wire bonding are crucial for meeting the shrinking form factors in memory, logic, and CMOS image sensor applications. Regulatory frameworks, particularly those governing semiconductor manufacturing and export controls, can influence market access and technology adoption. Competitive product substitutes, while not directly replacing wire bonding entirely, include advancements in wafer-level packaging and direct chip attach technologies, pushing wire bonder manufacturers to innovate continuously. End-user demographics are increasingly diverse, encompassing not only traditional consumer electronics but also burgeoning sectors like RF & MEMS, optoelectronics / photonics, and the automotive industry, all of which have unique bonding requirements. Mergers and acquisitions (M&A) are a notable trend, with companies seeking to consolidate expertise, expand product portfolios, and gain access to new markets. For instance, the pursuit of integrated solutions often leads to acquisitions.

- Market Concentration: Dominated by a mix of established global players and specialized regional manufacturers.

- Technological Innovation Drivers: Miniaturization, increased performance demands, and novel packaging architectures.

- Regulatory Frameworks: Export controls, trade policies, and environmental compliance.

- Competitive Product Substitutes: Advanced wafer-level packaging, flip-chip, and direct chip attach.

- End-User Demographics: Consumer Electronics, Automotive, Telecommunications, Medical Devices, and Aerospace.

- M&A Trends: Strategic acquisitions to broaden product offerings and enhance technological capabilities.

Wire Bonder Machines Industry Growth Trends & Insights

The global Wire Bonder Machines market is poised for significant expansion, driven by the insatiable demand for advanced semiconductor devices across a multitude of applications. The CAGR for the forecast period is projected at an impressive XX%, reflecting robust growth in semiconductor packaging solutions. Market penetration is steadily increasing as industries increasingly rely on sophisticated electronics, from smartphones and wearables to advanced automotive systems and the Internet of Things (IoT). Technological disruptions, such as the advent of hybrid bonding capable of achieving higher interconnect densities and improved electrical performance, are reshaping the competitive landscape. Consumer behavior shifts towards more compact, powerful, and energy-efficient devices directly translate into a greater need for advanced wire bonding capabilities. The adoption rates of state-of-the-art wire bonder machines are accelerating, particularly in high-growth application segments like memory, logic, and CMOS image sensors. Furthermore, the increasing complexity of integrated circuits necessitates precision bonding techniques that minimize signal loss and maximize reliability, thereby boosting the demand for sophisticated wire bonder machines. The growing emphasis on heterogenous integration, where multiple chiplets are assembled into a single package, further amplifies the need for versatile and high-throughput wire bonding solutions. Market size evolution is a direct consequence of these trends, with an estimated market size of $X,XXX Million units in 2025, projected to reach $Y,YYY Million units by 2033.

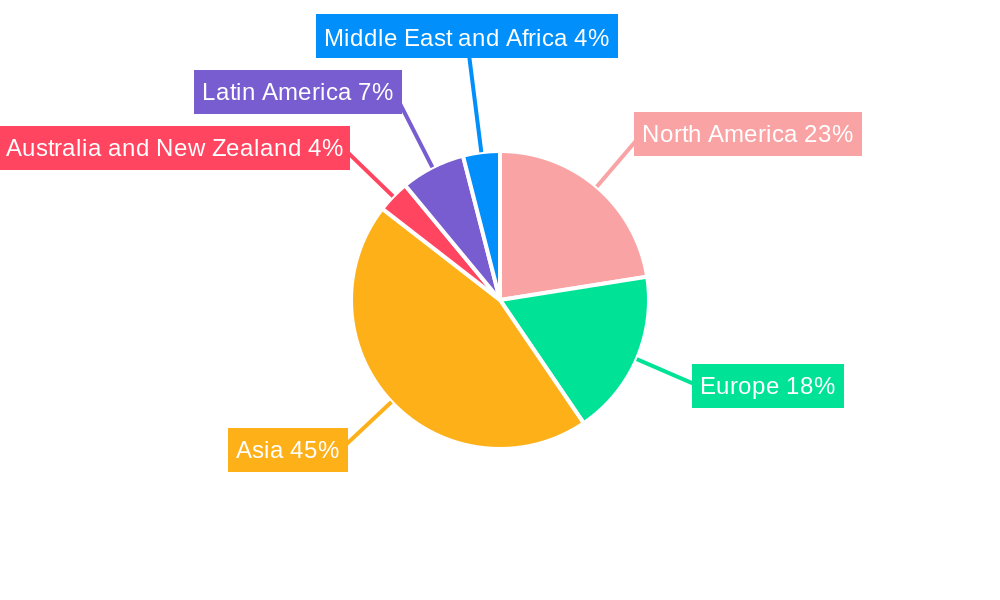

Dominant Regions, Countries, or Segments in Wire Bonder Machines Industry

The Asia Pacific region stands as the undisputed leader in the Wire Bonder Machines Industry, driven by its unparalleled concentration of semiconductor manufacturing and assembly facilities. Countries like China, South Korea, Taiwan, and Japan are at the forefront, housing a significant portion of global OSAT (Outsourced Semiconductor Assembly and Test) providers and integrated device manufacturers (IDMs). The dominance of this region is propelled by a confluence of factors including favorable government policies promoting the semiconductor industry, substantial investments in R&D, a highly skilled workforce, and the presence of major electronics manufacturers driving demand for advanced packaging. Within the Type segment, Die Bonder machines continue to command a substantial market share due to their foundational role in semiconductor assembly. However, the rapid growth of advanced applications is fueling significant expansion in the Flip Chip Bonder segment, particularly for high-performance processors and mobile devices.

In terms of Bonding Technique, Epoxy bonding remains widely adopted for its cost-effectiveness and versatility across numerous applications. Nevertheless, Eutectic and Soft Solder bonding techniques are critical for high-reliability and high-power applications, respectively. The emerging Hybrid Bonding technique is rapidly gaining traction, offering unprecedented interconnect density and electrical performance, making it crucial for next-generation semiconductor devices. This technique is a significant growth driver, especially for advanced memory and logic applications.

The Application landscape is dominated by Memory and Logic devices, which consistently represent the largest demand drivers due to the sheer volume of production in the consumer electronics and data center industries. However, the RF & MEMS and LED segments are experiencing robust growth, fueled by the proliferation of 5G technology, advanced sensor integration, and the increasing adoption of high-brightness LEDs in displays and lighting. The CMOS Image Sensor market is also a significant contributor, driven by the demand for higher resolution and more sophisticated camera modules in smartphones and other imaging devices. The growing importance of advanced packaging solutions for Optoelectronics / Photonics is also carving out a substantial niche.

- Dominant Region: Asia Pacific (China, South Korea, Taiwan, Japan).

- Key Drivers in Asia Pacific: Government support, massive manufacturing base, and strong demand from consumer electronics.

- Dominant Segment (Type): Die Bonder (with significant growth in Flip Chip Bonder).

- Dominant Segment (Bonding Technique): Epoxy (with strong growth in Hybrid Bonding).

- Dominant Segments (Application): Memory, Logic (with robust growth in RF & MEMS, LED, CMOS Image Sensor, Optoelectronics/Photonics).

Wire Bonder Machines Industry Product Landscape

The Wire Bonder Machines industry is witnessing continuous product innovation focused on enhancing precision, speed, and automation. Manufacturers are introducing machines capable of ultra-fine wire bonding for sub-micron pitch applications, crucial for next-generation microprocessors and memory devices. Advanced vision systems and AI-powered alignment technologies ensure sub-micron accuracy and defect detection, significantly improving yield. The integration of sophisticated hybrid bonding capabilities, enabling direct wafer-to-wafer or die-to-wafer interconnects, represents a paradigm shift, offering superior electrical performance and reduced form factors. Innovations in die attach processes, including advanced epoxy, eutectic, and soft solder dispensing systems, cater to diverse application needs, from high-temperature power devices to sensitive optical components. The development of modular and scalable equipment allows manufacturers to adapt to evolving production demands and customize solutions for specific applications in memory, logic, RF & MEMS, LED, CMOS Image Sensor, and optoelectronics/photonics.

Key Drivers, Barriers & Challenges in Wire Bonder Machines Industry

The Wire Bonder Machines Industry is propelled by several key drivers, including the relentless miniaturization of electronic components, the increasing complexity of semiconductor designs requiring advanced interconnects, and the burgeoning demand for high-performance computing and AI applications. The expansion of 5G infrastructure and the proliferation of IoT devices are further accelerating market growth. Strategic investments in advanced packaging technologies by major chip manufacturers are also a significant growth catalyst.

However, the industry faces notable barriers and challenges. The high cost of advanced wire bonder machines can be a significant hurdle for smaller manufacturers or those in emerging economies. Stringent quality control and reliability requirements in sectors like automotive and aerospace necessitate continuous investment in calibration and maintenance, adding to operational costs. Supply chain disruptions, particularly for specialized components and materials, can impact production timelines and increase costs. Furthermore, the rapid pace of technological evolution demands continuous R&D investment to stay competitive, posing a challenge for companies with limited resources. The skilled labor shortage for operating and maintaining these sophisticated machines also presents a persistent challenge.

Emerging Opportunities in Wire Bonder Machines Industry

Emerging opportunities within the Wire Bonder Machines Industry are significantly shaped by the growth of advanced semiconductor packaging and the demand for specialized devices. The burgeoning field of heterogeneous integration, where different chiplets are combined into a single package, presents a significant opportunity for wire bonder manufacturers to develop solutions supporting complex interconnectivity. The increasing adoption of advanced sensing technologies in automotive, medical, and industrial applications is creating a demand for precise and reliable bonding solutions for RF & MEMS and optoelectronics/photonics components. The expansion of advanced semiconductor manufacturing in new geographical regions beyond traditional hubs also offers untapped market potential. Furthermore, the development of more sustainable and environmentally friendly bonding materials and processes presents an opportunity for innovation and market differentiation. The increasing demand for high-performance computing and AI accelerators is also driving the need for ultra-high-density interconnects, a key area for innovation in wire bonding.

Growth Accelerators in the Wire Bonder Machines Industry Industry

Several factors are acting as significant growth accelerators for the Wire Bonder Machines Industry. The ongoing miniaturization trend in electronics, driven by consumer demand for smaller and more portable devices, continuously pushes the boundaries of wire bonding technology. The rise of AI and machine learning applications necessitates the development of increasingly powerful and complex semiconductor chips, directly translating into higher demand for advanced wire bonding capabilities. Strategic partnerships and collaborations between equipment manufacturers and semiconductor foundries are accelerating the development and adoption of next-generation bonding solutions. Furthermore, the expansion of the automotive electronics sector, with its increasing reliance on advanced sensors, processors, and communication modules, is a substantial growth driver. The growing trend towards industry 4.0 and smart manufacturing is also fostering the adoption of highly automated and intelligent wire bonding systems.

Key Players Shaping the Wire Bonder Machines Industry Market

- Inseto UK Limited

- MicroAssembly Technologies Ltd

- Palomar Technologies Inc

- Dr Tresky AG

- Kulicke and Soffa Industries Inc

- Fasford Technology Co Ltd

- ASM Pacific Technology Limited

- Shinkawa Ltd

- Be Semiconductor Industries N V

- Anza Technology Inc

Notable Milestones in Wire Bonder Machines Industry Sector

- November 2022: Indium Corporation, a US-based global materials supplier, opened a new 37,500-square-foot manufacturing facility in Malaysia. This facility manufactures Solder Pastes, Solder preforms, and Thermal Interface Materials, supporting die-attach and power semiconductor applications by enhancing productivity, performance, and efficiency.

- August 2022: Palomar Technologies, a provider of total process solutions for advanced photonics and microelectronic device packaging, expanded its Innovation Center in Singapore. This expansion aims to meet growing demand in Southeast Asia for outsourced semiconductor assembly and testing (OSAT) for advanced semiconductor new product introductions, featuring plasma cleaning, dry boxes, and customer-specific test equipment alongside existing die attach, wire bond, and vacuum reflow equipment.

In-Depth Wire Bonder Machines Industry Market Outlook

The future outlook for the Wire Bonder Machines Industry is exceptionally promising, fueled by sustained innovation and expanding application frontiers. The increasing demand for advanced packaging solutions in AI, 5G, IoT, and automotive electronics will continue to drive the adoption of sophisticated wire bonding technologies. The ongoing advancements in hybrid bonding offer significant potential for breakthroughs in interconnect density and device performance, opening new avenues for miniaturization and functionality. Strategic expansions by key players into emerging markets and the continuous pursuit of enhanced automation and intelligent manufacturing processes will further accelerate market growth. The industry is well-positioned to capitalize on the trend towards heterogenous integration and the development of specialized semiconductor devices, ensuring robust long-term market potential and continued strategic opportunities for stakeholders.

Wire Bonder Machines Industry Segmentation

-

1. Type

- 1.1. Die Bonder

- 1.2. Flip Chip Bonder

-

2. Bonding Technique

- 2.1. Epoxy

- 2.2. Eutectic

- 2.3. Soft Solder

- 2.4. Hybrid Bonding

- 2.5. Other Bonding Techniques

-

3. Application

- 3.1. Memory

- 3.2. RF & MEMS

- 3.3. LED

- 3.4. CMOS Image Sensor

- 3.5. Logic

- 3.6. Optoelectronics / Photonics

- 3.7. Other Applications

Wire Bonder Machines Industry Segmentation By Geography

- 1. North America

- 2. Europe

- 3. Asia

- 4. Australia and New Zealand

- 5. Latin America

- 6. Middle East and Africa

Wire Bonder Machines Industry Regional Market Share

Geographic Coverage of Wire Bonder Machines Industry

Wire Bonder Machines Industry REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 6.09% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. Growing Demand of AuSn Eutectic Die-Attach Technology; Demand of Discrete Power Devices; LED Segment to Witness Significant Growth

- 3.3. Market Restrains

- 3.3.1. Dimensional Changes During Processing and Service Life and Mechanical Unbalance

- 3.4. Market Trends

- 3.4.1. LED to Witness Significant Growth

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global Wire Bonder Machines Industry Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Type

- 5.1.1. Die Bonder

- 5.1.2. Flip Chip Bonder

- 5.2. Market Analysis, Insights and Forecast - by Bonding Technique

- 5.2.1. Epoxy

- 5.2.2. Eutectic

- 5.2.3. Soft Solder

- 5.2.4. Hybrid Bonding

- 5.2.5. Other Bonding Techniques

- 5.3. Market Analysis, Insights and Forecast - by Application

- 5.3.1. Memory

- 5.3.2. RF & MEMS

- 5.3.3. LED

- 5.3.4. CMOS Image Sensor

- 5.3.5. Logic

- 5.3.6. Optoelectronics / Photonics

- 5.3.7. Other Applications

- 5.4. Market Analysis, Insights and Forecast - by Region

- 5.4.1. North America

- 5.4.2. Europe

- 5.4.3. Asia

- 5.4.4. Australia and New Zealand

- 5.4.5. Latin America

- 5.4.6. Middle East and Africa

- 5.1. Market Analysis, Insights and Forecast - by Type

- 6. North America Wire Bonder Machines Industry Analysis, Insights and Forecast, 2020-2032

- 6.1. Market Analysis, Insights and Forecast - by Type

- 6.1.1. Die Bonder

- 6.1.2. Flip Chip Bonder

- 6.2. Market Analysis, Insights and Forecast - by Bonding Technique

- 6.2.1. Epoxy

- 6.2.2. Eutectic

- 6.2.3. Soft Solder

- 6.2.4. Hybrid Bonding

- 6.2.5. Other Bonding Techniques

- 6.3. Market Analysis, Insights and Forecast - by Application

- 6.3.1. Memory

- 6.3.2. RF & MEMS

- 6.3.3. LED

- 6.3.4. CMOS Image Sensor

- 6.3.5. Logic

- 6.3.6. Optoelectronics / Photonics

- 6.3.7. Other Applications

- 6.1. Market Analysis, Insights and Forecast - by Type

- 7. Europe Wire Bonder Machines Industry Analysis, Insights and Forecast, 2020-2032

- 7.1. Market Analysis, Insights and Forecast - by Type

- 7.1.1. Die Bonder

- 7.1.2. Flip Chip Bonder

- 7.2. Market Analysis, Insights and Forecast - by Bonding Technique

- 7.2.1. Epoxy

- 7.2.2. Eutectic

- 7.2.3. Soft Solder

- 7.2.4. Hybrid Bonding

- 7.2.5. Other Bonding Techniques

- 7.3. Market Analysis, Insights and Forecast - by Application

- 7.3.1. Memory

- 7.3.2. RF & MEMS

- 7.3.3. LED

- 7.3.4. CMOS Image Sensor

- 7.3.5. Logic

- 7.3.6. Optoelectronics / Photonics

- 7.3.7. Other Applications

- 7.1. Market Analysis, Insights and Forecast - by Type

- 8. Asia Wire Bonder Machines Industry Analysis, Insights and Forecast, 2020-2032

- 8.1. Market Analysis, Insights and Forecast - by Type

- 8.1.1. Die Bonder

- 8.1.2. Flip Chip Bonder

- 8.2. Market Analysis, Insights and Forecast - by Bonding Technique

- 8.2.1. Epoxy

- 8.2.2. Eutectic

- 8.2.3. Soft Solder

- 8.2.4. Hybrid Bonding

- 8.2.5. Other Bonding Techniques

- 8.3. Market Analysis, Insights and Forecast - by Application

- 8.3.1. Memory

- 8.3.2. RF & MEMS

- 8.3.3. LED

- 8.3.4. CMOS Image Sensor

- 8.3.5. Logic

- 8.3.6. Optoelectronics / Photonics

- 8.3.7. Other Applications

- 8.1. Market Analysis, Insights and Forecast - by Type

- 9. Australia and New Zealand Wire Bonder Machines Industry Analysis, Insights and Forecast, 2020-2032

- 9.1. Market Analysis, Insights and Forecast - by Type

- 9.1.1. Die Bonder

- 9.1.2. Flip Chip Bonder

- 9.2. Market Analysis, Insights and Forecast - by Bonding Technique

- 9.2.1. Epoxy

- 9.2.2. Eutectic

- 9.2.3. Soft Solder

- 9.2.4. Hybrid Bonding

- 9.2.5. Other Bonding Techniques

- 9.3. Market Analysis, Insights and Forecast - by Application

- 9.3.1. Memory

- 9.3.2. RF & MEMS

- 9.3.3. LED

- 9.3.4. CMOS Image Sensor

- 9.3.5. Logic

- 9.3.6. Optoelectronics / Photonics

- 9.3.7. Other Applications

- 9.1. Market Analysis, Insights and Forecast - by Type

- 10. Latin America Wire Bonder Machines Industry Analysis, Insights and Forecast, 2020-2032

- 10.1. Market Analysis, Insights and Forecast - by Type

- 10.1.1. Die Bonder

- 10.1.2. Flip Chip Bonder

- 10.2. Market Analysis, Insights and Forecast - by Bonding Technique

- 10.2.1. Epoxy

- 10.2.2. Eutectic

- 10.2.3. Soft Solder

- 10.2.4. Hybrid Bonding

- 10.2.5. Other Bonding Techniques

- 10.3. Market Analysis, Insights and Forecast - by Application

- 10.3.1. Memory

- 10.3.2. RF & MEMS

- 10.3.3. LED

- 10.3.4. CMOS Image Sensor

- 10.3.5. Logic

- 10.3.6. Optoelectronics / Photonics

- 10.3.7. Other Applications

- 10.1. Market Analysis, Insights and Forecast - by Type

- 11. Middle East and Africa Wire Bonder Machines Industry Analysis, Insights and Forecast, 2020-2032

- 11.1. Market Analysis, Insights and Forecast - by Type

- 11.1.1. Die Bonder

- 11.1.2. Flip Chip Bonder

- 11.2. Market Analysis, Insights and Forecast - by Bonding Technique

- 11.2.1. Epoxy

- 11.2.2. Eutectic

- 11.2.3. Soft Solder

- 11.2.4. Hybrid Bonding

- 11.2.5. Other Bonding Techniques

- 11.3. Market Analysis, Insights and Forecast - by Application

- 11.3.1. Memory

- 11.3.2. RF & MEMS

- 11.3.3. LED

- 11.3.4. CMOS Image Sensor

- 11.3.5. Logic

- 11.3.6. Optoelectronics / Photonics

- 11.3.7. Other Applications

- 11.1. Market Analysis, Insights and Forecast - by Type

- 12. Competitive Analysis

- 12.1. Global Market Share Analysis 2025

- 12.2. Company Profiles

- 12.2.1 Inseto UK Limited

- 12.2.1.1. Overview

- 12.2.1.2. Products

- 12.2.1.3. SWOT Analysis

- 12.2.1.4. Recent Developments

- 12.2.1.5. Financials (Based on Availability)

- 12.2.2 MicroAssembly Technologies Ltd

- 12.2.2.1. Overview

- 12.2.2.2. Products

- 12.2.2.3. SWOT Analysis

- 12.2.2.4. Recent Developments

- 12.2.2.5. Financials (Based on Availability)

- 12.2.3 Palomar Technologies Inc

- 12.2.3.1. Overview

- 12.2.3.2. Products

- 12.2.3.3. SWOT Analysis

- 12.2.3.4. Recent Developments

- 12.2.3.5. Financials (Based on Availability)

- 12.2.4 Dr Tresky AG

- 12.2.4.1. Overview

- 12.2.4.2. Products

- 12.2.4.3. SWOT Analysis

- 12.2.4.4. Recent Developments

- 12.2.4.5. Financials (Based on Availability)

- 12.2.5 Kulicke and Soffa Industries Inc

- 12.2.5.1. Overview

- 12.2.5.2. Products

- 12.2.5.3. SWOT Analysis

- 12.2.5.4. Recent Developments

- 12.2.5.5. Financials (Based on Availability)

- 12.2.6 Fasford Technology Co Ltd

- 12.2.6.1. Overview

- 12.2.6.2. Products

- 12.2.6.3. SWOT Analysis

- 12.2.6.4. Recent Developments

- 12.2.6.5. Financials (Based on Availability)

- 12.2.7 ASM Pacific Technology Limited

- 12.2.7.1. Overview

- 12.2.7.2. Products

- 12.2.7.3. SWOT Analysis

- 12.2.7.4. Recent Developments

- 12.2.7.5. Financials (Based on Availability)

- 12.2.8 Shinkawa Ltd

- 12.2.8.1. Overview

- 12.2.8.2. Products

- 12.2.8.3. SWOT Analysis

- 12.2.8.4. Recent Developments

- 12.2.8.5. Financials (Based on Availability)

- 12.2.9 Be Semiconductor Industries N V

- 12.2.9.1. Overview

- 12.2.9.2. Products

- 12.2.9.3. SWOT Analysis

- 12.2.9.4. Recent Developments

- 12.2.9.5. Financials (Based on Availability)

- 12.2.10 Anza Technology Inc *List Not Exhaustive

- 12.2.10.1. Overview

- 12.2.10.2. Products

- 12.2.10.3. SWOT Analysis

- 12.2.10.4. Recent Developments

- 12.2.10.5. Financials (Based on Availability)

- 12.2.1 Inseto UK Limited

List of Figures

- Figure 1: Global Wire Bonder Machines Industry Revenue Breakdown (Million, %) by Region 2025 & 2033

- Figure 2: North America Wire Bonder Machines Industry Revenue (Million), by Type 2025 & 2033

- Figure 3: North America Wire Bonder Machines Industry Revenue Share (%), by Type 2025 & 2033

- Figure 4: North America Wire Bonder Machines Industry Revenue (Million), by Bonding Technique 2025 & 2033

- Figure 5: North America Wire Bonder Machines Industry Revenue Share (%), by Bonding Technique 2025 & 2033

- Figure 6: North America Wire Bonder Machines Industry Revenue (Million), by Application 2025 & 2033

- Figure 7: North America Wire Bonder Machines Industry Revenue Share (%), by Application 2025 & 2033

- Figure 8: North America Wire Bonder Machines Industry Revenue (Million), by Country 2025 & 2033

- Figure 9: North America Wire Bonder Machines Industry Revenue Share (%), by Country 2025 & 2033

- Figure 10: Europe Wire Bonder Machines Industry Revenue (Million), by Type 2025 & 2033

- Figure 11: Europe Wire Bonder Machines Industry Revenue Share (%), by Type 2025 & 2033

- Figure 12: Europe Wire Bonder Machines Industry Revenue (Million), by Bonding Technique 2025 & 2033

- Figure 13: Europe Wire Bonder Machines Industry Revenue Share (%), by Bonding Technique 2025 & 2033

- Figure 14: Europe Wire Bonder Machines Industry Revenue (Million), by Application 2025 & 2033

- Figure 15: Europe Wire Bonder Machines Industry Revenue Share (%), by Application 2025 & 2033

- Figure 16: Europe Wire Bonder Machines Industry Revenue (Million), by Country 2025 & 2033

- Figure 17: Europe Wire Bonder Machines Industry Revenue Share (%), by Country 2025 & 2033

- Figure 18: Asia Wire Bonder Machines Industry Revenue (Million), by Type 2025 & 2033

- Figure 19: Asia Wire Bonder Machines Industry Revenue Share (%), by Type 2025 & 2033

- Figure 20: Asia Wire Bonder Machines Industry Revenue (Million), by Bonding Technique 2025 & 2033

- Figure 21: Asia Wire Bonder Machines Industry Revenue Share (%), by Bonding Technique 2025 & 2033

- Figure 22: Asia Wire Bonder Machines Industry Revenue (Million), by Application 2025 & 2033

- Figure 23: Asia Wire Bonder Machines Industry Revenue Share (%), by Application 2025 & 2033

- Figure 24: Asia Wire Bonder Machines Industry Revenue (Million), by Country 2025 & 2033

- Figure 25: Asia Wire Bonder Machines Industry Revenue Share (%), by Country 2025 & 2033

- Figure 26: Australia and New Zealand Wire Bonder Machines Industry Revenue (Million), by Type 2025 & 2033

- Figure 27: Australia and New Zealand Wire Bonder Machines Industry Revenue Share (%), by Type 2025 & 2033

- Figure 28: Australia and New Zealand Wire Bonder Machines Industry Revenue (Million), by Bonding Technique 2025 & 2033

- Figure 29: Australia and New Zealand Wire Bonder Machines Industry Revenue Share (%), by Bonding Technique 2025 & 2033

- Figure 30: Australia and New Zealand Wire Bonder Machines Industry Revenue (Million), by Application 2025 & 2033

- Figure 31: Australia and New Zealand Wire Bonder Machines Industry Revenue Share (%), by Application 2025 & 2033

- Figure 32: Australia and New Zealand Wire Bonder Machines Industry Revenue (Million), by Country 2025 & 2033

- Figure 33: Australia and New Zealand Wire Bonder Machines Industry Revenue Share (%), by Country 2025 & 2033

- Figure 34: Latin America Wire Bonder Machines Industry Revenue (Million), by Type 2025 & 2033

- Figure 35: Latin America Wire Bonder Machines Industry Revenue Share (%), by Type 2025 & 2033

- Figure 36: Latin America Wire Bonder Machines Industry Revenue (Million), by Bonding Technique 2025 & 2033

- Figure 37: Latin America Wire Bonder Machines Industry Revenue Share (%), by Bonding Technique 2025 & 2033

- Figure 38: Latin America Wire Bonder Machines Industry Revenue (Million), by Application 2025 & 2033

- Figure 39: Latin America Wire Bonder Machines Industry Revenue Share (%), by Application 2025 & 2033

- Figure 40: Latin America Wire Bonder Machines Industry Revenue (Million), by Country 2025 & 2033

- Figure 41: Latin America Wire Bonder Machines Industry Revenue Share (%), by Country 2025 & 2033

- Figure 42: Middle East and Africa Wire Bonder Machines Industry Revenue (Million), by Type 2025 & 2033

- Figure 43: Middle East and Africa Wire Bonder Machines Industry Revenue Share (%), by Type 2025 & 2033

- Figure 44: Middle East and Africa Wire Bonder Machines Industry Revenue (Million), by Bonding Technique 2025 & 2033

- Figure 45: Middle East and Africa Wire Bonder Machines Industry Revenue Share (%), by Bonding Technique 2025 & 2033

- Figure 46: Middle East and Africa Wire Bonder Machines Industry Revenue (Million), by Application 2025 & 2033

- Figure 47: Middle East and Africa Wire Bonder Machines Industry Revenue Share (%), by Application 2025 & 2033

- Figure 48: Middle East and Africa Wire Bonder Machines Industry Revenue (Million), by Country 2025 & 2033

- Figure 49: Middle East and Africa Wire Bonder Machines Industry Revenue Share (%), by Country 2025 & 2033

List of Tables

- Table 1: Global Wire Bonder Machines Industry Revenue Million Forecast, by Type 2020 & 2033

- Table 2: Global Wire Bonder Machines Industry Revenue Million Forecast, by Bonding Technique 2020 & 2033

- Table 3: Global Wire Bonder Machines Industry Revenue Million Forecast, by Application 2020 & 2033

- Table 4: Global Wire Bonder Machines Industry Revenue Million Forecast, by Region 2020 & 2033

- Table 5: Global Wire Bonder Machines Industry Revenue Million Forecast, by Type 2020 & 2033

- Table 6: Global Wire Bonder Machines Industry Revenue Million Forecast, by Bonding Technique 2020 & 2033

- Table 7: Global Wire Bonder Machines Industry Revenue Million Forecast, by Application 2020 & 2033

- Table 8: Global Wire Bonder Machines Industry Revenue Million Forecast, by Country 2020 & 2033

- Table 9: Global Wire Bonder Machines Industry Revenue Million Forecast, by Type 2020 & 2033

- Table 10: Global Wire Bonder Machines Industry Revenue Million Forecast, by Bonding Technique 2020 & 2033

- Table 11: Global Wire Bonder Machines Industry Revenue Million Forecast, by Application 2020 & 2033

- Table 12: Global Wire Bonder Machines Industry Revenue Million Forecast, by Country 2020 & 2033

- Table 13: Global Wire Bonder Machines Industry Revenue Million Forecast, by Type 2020 & 2033

- Table 14: Global Wire Bonder Machines Industry Revenue Million Forecast, by Bonding Technique 2020 & 2033

- Table 15: Global Wire Bonder Machines Industry Revenue Million Forecast, by Application 2020 & 2033

- Table 16: Global Wire Bonder Machines Industry Revenue Million Forecast, by Country 2020 & 2033

- Table 17: Global Wire Bonder Machines Industry Revenue Million Forecast, by Type 2020 & 2033

- Table 18: Global Wire Bonder Machines Industry Revenue Million Forecast, by Bonding Technique 2020 & 2033

- Table 19: Global Wire Bonder Machines Industry Revenue Million Forecast, by Application 2020 & 2033

- Table 20: Global Wire Bonder Machines Industry Revenue Million Forecast, by Country 2020 & 2033

- Table 21: Global Wire Bonder Machines Industry Revenue Million Forecast, by Type 2020 & 2033

- Table 22: Global Wire Bonder Machines Industry Revenue Million Forecast, by Bonding Technique 2020 & 2033

- Table 23: Global Wire Bonder Machines Industry Revenue Million Forecast, by Application 2020 & 2033

- Table 24: Global Wire Bonder Machines Industry Revenue Million Forecast, by Country 2020 & 2033

- Table 25: Global Wire Bonder Machines Industry Revenue Million Forecast, by Type 2020 & 2033

- Table 26: Global Wire Bonder Machines Industry Revenue Million Forecast, by Bonding Technique 2020 & 2033

- Table 27: Global Wire Bonder Machines Industry Revenue Million Forecast, by Application 2020 & 2033

- Table 28: Global Wire Bonder Machines Industry Revenue Million Forecast, by Country 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Wire Bonder Machines Industry?

The projected CAGR is approximately 6.09%.

2. Which companies are prominent players in the Wire Bonder Machines Industry?

Key companies in the market include Inseto UK Limited, MicroAssembly Technologies Ltd, Palomar Technologies Inc, Dr Tresky AG, Kulicke and Soffa Industries Inc, Fasford Technology Co Ltd, ASM Pacific Technology Limited, Shinkawa Ltd, Be Semiconductor Industries N V, Anza Technology Inc *List Not Exhaustive.

3. What are the main segments of the Wire Bonder Machines Industry?

The market segments include Type, Bonding Technique, Application.

4. Can you provide details about the market size?

The market size is estimated to be USD 1.45 Million as of 2022.

5. What are some drivers contributing to market growth?

Growing Demand of AuSn Eutectic Die-Attach Technology; Demand of Discrete Power Devices; LED Segment to Witness Significant Growth.

6. What are the notable trends driving market growth?

LED to Witness Significant Growth.

7. Are there any restraints impacting market growth?

Dimensional Changes During Processing and Service Life and Mechanical Unbalance.

8. Can you provide examples of recent developments in the market?

November 2022 - Indium Corporation, a US-based global materials supplier to the electronics assembly and semiconductor packaging industries, opened its new 37,500-square-foot manufacturing facility in Malaysia. The new facility manufactures Solder Pastes, Solder preforms, and Thermal Interface Materials. This Indium Corporation's proven, innovative material solutions for die-attach and power semiconductor applications are designed to increase productivity, performance, and efficiency.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4750, USD 5250, and USD 8750 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in Million.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Wire Bonder Machines Industry," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Wire Bonder Machines Industry report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Wire Bonder Machines Industry?

To stay informed about further developments, trends, and reports in the Wire Bonder Machines Industry, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

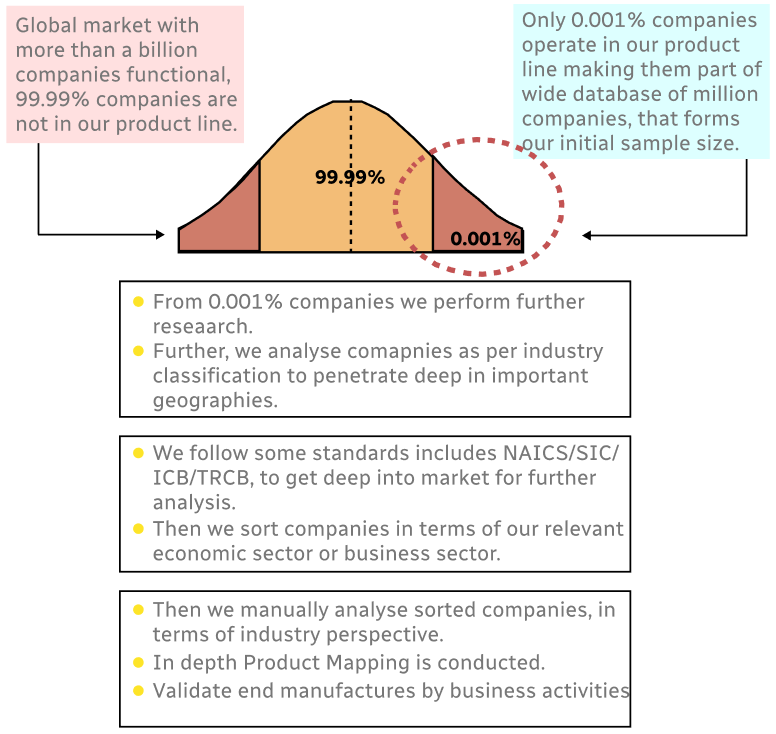

Step 1 - Identification of Relevant Samples Size from Population Database

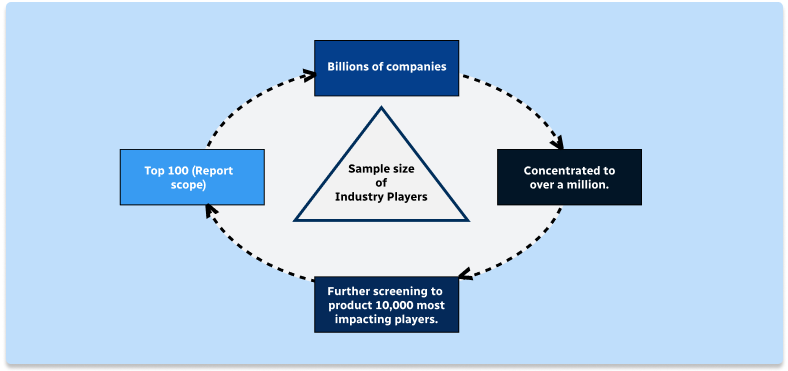

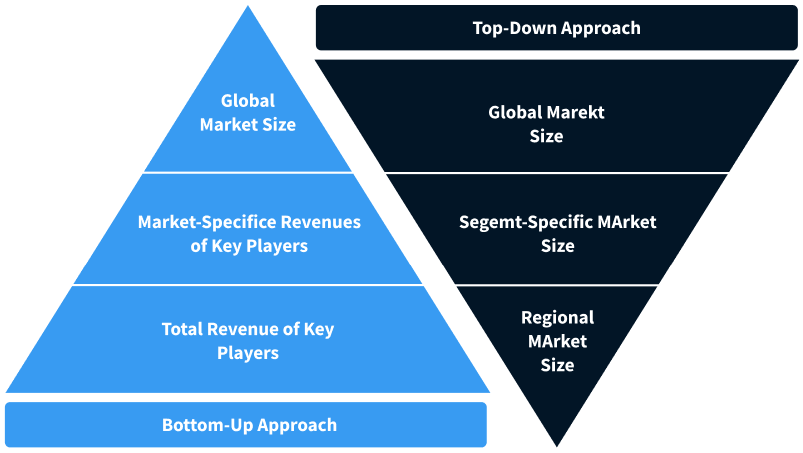

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

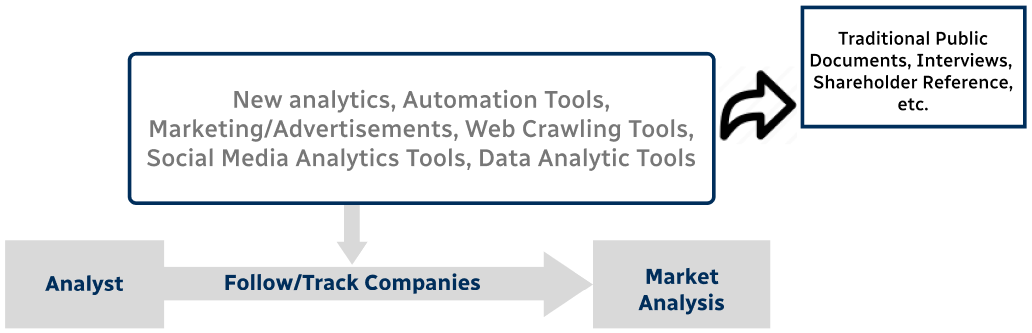

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence